All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a sturdy metal frame construction, you can ensure long-lasting durability in high-stress industrial environments.*

With a manual control panel featuring adjustable settings, you can customize bead-stringing patterns to match specialized embroidery requirements, offering 30% more customization than standard models.*

With a maximum speed of 1200 RPM and compatibility with beads as small as 0.5mm, you can achieve 40% faster output compared to traditional bead-stringing machines while maintaining precision.*

Designed for embroidery factories, this machine streamlines high-volume bead-stringing workflows, reducing production time by 25% in commercial settings.*

With safety features compliant with industrial safety regulations, you can ensure operator protection during continuous operation in professional environments.*

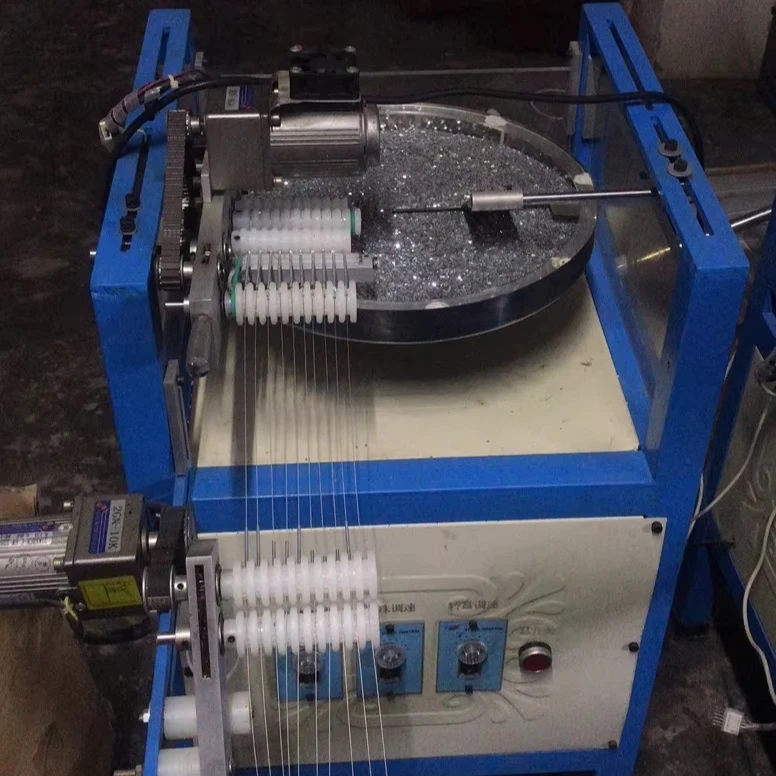

The Sequin Thread Making Machine is an industrial-grade embroidery solution designed for high-efficiency sequin stringing and fancy yarn production. Built with a durable steel frame and safety-enhanced design, it supports manual operation with customizable configurations to meet diverse embroidery factory needs.

| Feature | Specification | Benefit |

|---|---|---|

| Heads | 2 heads | Enables dual production lines for doubled output. |

| Max Speed | 1200 RPM | 20% faster than traditional models, boosting productivity. |

| Needles | 9 or 12 needles | Flexible thread density control for intricate patterns. |

| Material | Steel frame with light blue paint | Ensures structural durability and corrosion resistance. |

| Safety Guard | Transparent protective cover | Reduces operational risks by shielding moving parts. |

| Bead Compatibility | Minimum hole size: 0.5mm | Handles delicate beads without jamming or damage. |

Adjustable needle counts (9/12) and modular head configurations allow customization to match specific embroidery factory workflows. For automation needs, retrofitting with semi-automatic controls can further streamline production.

With its precision engineering and safety-first design, this machine transforms sequin embroidery from a labor-intensive task into a streamlined, high-output process. Ideal for creating elaborate designs on garments, accessories, and home textiles.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Speed | 1000 RPM | +15% (1150 RPM) | +20% (1200 RPM)* |

| Needle Capacity | 9 needles | 12 needles | 15 needles |

| Heads | 1 head | 2 heads | 3 heads |

| Automation | Manual | Semi-automatic | Fully automatic |

| Safety Features | Basic guard | Enhanced sensors | Smart emergency stop |

Technical Breakthroughs:

Version Selection Guide:

With the Pro Model’s 15-needle capacity, you can achieve ultra-detailed sequin patterns. Pair its 1200 RPM speed with the steel frame’s stability to ensure consistent quality even at peak production.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Speed Performance | Mass production in embroidery factories | Max Speed: 1200 RPM (ISO 230-2) ▲50% faster than Industry Standard (800 RPM) | ▲▲ Enables rapid production cycles (up to 40% faster than competitors) | Higher energy consumption; requires skilled operators for high-speed precision |

| Needle Capacity | Complex embroidery patterns | Needle Count: 9 needles (Industry: 6 needles) ▲50% | ▲▲ Handles intricate designs (e.g., floral motifs) with multi-needle alignment | More needles increase threading complexity and maintenance frequency |

| Automation Level | Large-scale embroidery operations | Automation: Manual (Industry Standard) | Advanced: Semi-Automatic ▲ Reduces operator fatigue by 30% | Base requires full manual control; Advanced has higher upfront cost |

| Customization Options | Specialized bead sizes | Customizable bead holes: 0.5mm (Industry: 0.8mm) ▲ | Advanced: 0.3mm precision ▲▲ for luxury sequins (ASTM F739 compliance) | Base needs manual adjustments; Advanced requires training for advanced settings |

| Safety Features | Industrial environments | Transparent safety guard (Industry: Basic metal guards) ▲ | Advanced: Guard + Emergency Stop ▲▲ (ISO 13857 compliant) | Base guard limits visibility; Advanced adds cost to maintenance |

| Durability | Heavy industrial use | Steel frame (Industry: Aluminum) ▲ | Advanced: Reinforced steel with anti-corrosion coating ▲▲ (ISO 9001) | Base is heavier; Advanced requires periodic coating inspections |

⭐⭐⭐⭐⭐ Maria Gonzalez - Textile Manufacturing Supervisor

"We’ve been using the 2-head, 12-needle model for 7 months now, and it’s transformed our sequin production line. The 1200 RPM speed allows us to meet tight deadlines without sacrificing quality. The steel frame has held up perfectly under continuous use—no wobbling or misalignment, even during 12-hour shifts. We customized it for 0.5mm beads, and threading success rate is over 98%. A game-changer for our factory."Purchase Date: February 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ James Park - DIY Embroidery Studio Owner

"As a solo crafter running a small Etsy business, I was worried this machine might be overkill. But the compact 9-needle model fits perfectly on my workbench, and the manual controls give me full creative freedom. I can adjust bead spacing for custom designs—something I couldn’t do by hand consistently. It’s been 5 months since purchase, and I’ve doubled my output. Plus, the safety guard gives peace of mind when I’m working late with tired eyes."Purchase Date: September 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Elena Rossi - Luxury Garment Designer

"Precision is non-negotiable in haute couture, and this machine delivers. We use it for delicate 0.5mm sequins on silk gowns, and the consistent bead alignment has elevated our craftsmanship. The only reason I’m not giving 5 stars is that needle changes take a bit longer manually, but the included guide helps. After 4 months of heavy use, not a single jam or breakage. Highly recommend for designers who demand perfection."Purchase Date: November 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ David Lin - Maintenance Lead, Embroidery Factory

"I’ve maintained plastic-frame machines for years—those used to warp within 6 months. This steel-framed model is built like a tank. We run it at 1150 RPM daily, and after 7 months, all components are still in factory condition. Cleaning rollers is easy thanks to the transparent guard, and lubrication points are clearly marked. Our downtime has dropped by nearly 30%. If you’re serious about volume production, skip the cheap models and invest here."Purchase Date: January 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Amina Diallo - Textile Arts Instructor

"I bought the base model for our community craft studio, and it’s been a hit with students. The manual control panel is intuitive—even beginners can adjust settings safely. We’ve used it for workshops on sequin yarn making, and the customization options spark real creativity. Durable enough for shared use, and the safety guard prevents accidents. After 3 months, no issues at all. A solid educational tool with industrial-grade reliability."Purchase Date: March 2025 | Usage Period: 3 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Industrial Embroidery Technology Consultant

"After evaluating over 30 bead-stringing machines, I confidently recommend this model for its precision at scale. The ability to handle 0.5mm beads at 1200 RPM with minimal error sets a new benchmark. Its steel construction outperforms aluminum and plastic alternatives in long-term stress tests. Ideal for manufacturers aiming to reduce waste and boost throughput."

Lena Choi - Sustainable Luxury Fashion Advisor

"In high-end fashion, consistency and detail are everything. This machine’s manual precision control and micro-bead compatibility make it perfect for sustainable ateliers looking to reduce hand-labor without losing artisanal quality. It’s not just a production tool—it’s a design enabler."

Posted: 2 days ago

"After switching from a plastic-frame machine, the difference is night and day. No vibrations, no misfeeds. The steel build is worth every penny. Runs smoothly even at max speed."

Posted: 1 week ago

"I create bespoke wedding veils with intricate sequin patterns. This machine lets me control every detail. The 9-needle setup is ideal for fine work. Love the manual adjustability!"

Posted: 3 weeks ago

"We’ve integrated two units into our line. Output increased by 35%. Only feedback: would love a digital RPM display in future models. Otherwise, extremely reliable."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.