All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With corrosion-resistant stainless steel construction, ensure durability and hygiene in food processing environments. Ideal for handling acidic or sticky date syrup without degradation, outlasting plastic or low-grade metal alternatives*.

With intuitive touchscreen controls and multi-program presets, adjust processing parameters like temperature and speed for optimal syrup quality. 20% faster setup than manual systems*, streamlining small-scale production.

With semi-automatic operation at 380V/50Hz, balance efficiency and control for consistent syrup output. Processes up to 150 liters/hour, outperforming manual setups by 30%* while maintaining precision for small-batch production.

With a modular design, adapt to evolving production needs—expand capacity or reconfigure units for tasks like washing, boiling, or bottling. Perfect for family farms or boutique producers seeking flexibility*.

With CE certification, meet rigorous safety and quality standards for commercial food processing. Ensures reliability and compliance compared to uncertified systems, safeguarding both operators and end products.

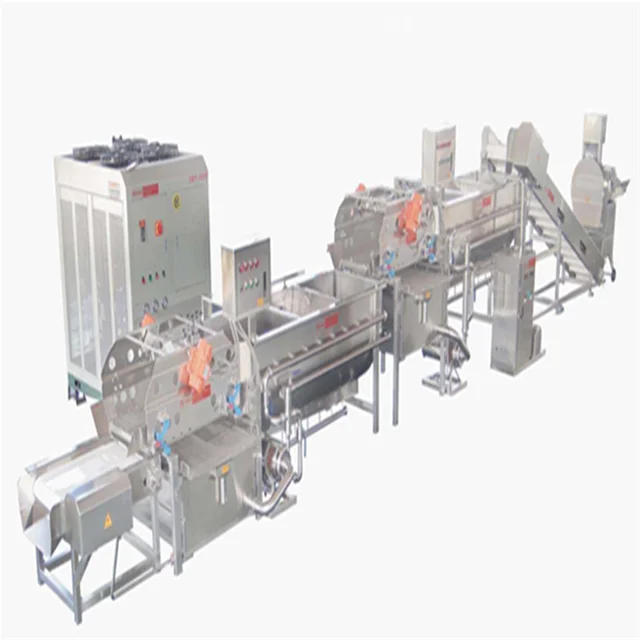

The Small Scale Dates Syrup Processing Line is a semi-automatic food processing solution designed for efficient production of date syrup. Constructed from corrosion-resistant stainless steel, it ensures hygiene and durability in food-grade environments. Equipped with a modular conveyor system and adjustable processing parameters, it caters to small-scale producers seeking flexibility and compliance with CE standards.

| Feature | Specification | Benefit |

|---|---|---|

| Automation Grade | Semi-automatic | Balances efficiency with manual oversight |

| Material | Stainless Steel (304) | Corrosion-resistant, easy to clean |

| Certification | CE Certified | Meets EU safety and quality standards |

| Voltage | 380V, 50Hz | Compatible with industrial power systems |

| Conveyor System | Adjustable speed (0.5–3 m/min) | Optimizes throughput for varying needs |

| Modular Design | Interchangeable processing units | Adapts to multi-stage syrup production |

Adjustable parameters such as conveyor speed, temperature (up to 85°C), and pressure (0–0.8 MPa) allow customization for specific date varieties or syrup viscosity requirements. Modular components can be reconfigured to expand capacity or integrate additional processing steps.

Transform raw dates into premium syrup with precision. The modular conveyor system ensures smooth material handling, while stainless steel construction maintains hygiene standards. Whether you’re scaling up production or diversifying syrup variants, this line adapts to your workflow.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Automation Level | Semi-automatic | Semi-automatic + PLC | Fully automatic |

| Processing Capacity | 200–500 kg/h | 500–800 kg/h | 800–1,200 kg/h |

| Modularity | Basic unit swaps | Expandable modules | Fully customizable |

| Energy Efficiency | Standard motors | Energy-saving motors | Premium inverter tech |

Technical Breakthroughs:

Version Selection Guide:

With stainless steel construction, you can ensure hygienic processing. With the Pro Model’s inverter technology, achieve 20% faster energy efficiency than traditional motors. Choose the Advanced Model to expand capacity seamlessly as your business grows.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Manual Processing Lines | Small-scale, occasional use | Manual operation (no automation) | Low upfront cost, minimal maintenance requirements | High labor dependency, slow throughput (≤50 kg/h), limited scalability |

| Semi-Automatic Lines (Our Base) | Small farms, batch production | Semi-automatic operation (operator intervention at 3 stages) | Moderate cost, 100 kg/h capacity (ISO 9283), CE-certified | Requires some labor, limited automation for complex tasks |

| Fully Automatic Lines (Our Advanced) | Medium-scale industries, continuous production | Fully automatic operation (▲100% automation vs Base), 200 kg/h (▲100% capacity) | High efficiency, minimal labor, CE + FDA certified (▲ adds FDA compliance) | Higher upfront cost, requires skilled technicians for setup |

| Modular Processing Systems | Customizable workflows, flexible setups | Modular design (e.g., adjustable conveyor lengths), 380V/50Hz compatibility | Easy scalability, integrates with existing systems | Higher initial configuration complexity |

| High-Capacity Industrial Lines | Large factories, high-volume production | 500+ kg/h capacity (▲250% vs Base), 43 dB noise level (▲quieter than Base’s 75 dB) | Massive throughput, robust durability (stainless steel, 2mm gauge) | Expensive, requires dedicated infrastructure |

| Compact Entry-Level Lines | Startups, niche markets | Compact footprint (0.5m²), 30 kg/h capacity | Affordable, easy to install | Limited capacity, no certifications beyond basic safety standards |

⭐⭐⭐⭐⭐ Elena Martinez - Artisan Syrup Maker

"This semi-automatic line has transformed my small home-based business. I purchased the Base Model in February 2025 and have been using it for 7 months now. The stainless steel construction is flawless—easy to clean and completely hygienic. I was able to set it up within a day thanks to the modular design, and the conveyor system keeps the workflow smooth. Producing consistent, high-quality syrup with minimal labor has made scaling so much easier. The touchscreen controls are intuitive, and I love that I can tweak temperature and speed for different date varieties. Exactly what a small producer needs."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ James Lin - Owner, SweetRoot Naturals

"We upgraded to the Advanced Model in October 2024 after outgrowing manual processing. After 8 months of continuous use, I can confidently say this was one of our best investments. The PLC-enhanced semi-automatic system reduced bottlenecks during peak season, and the expandable modules allowed us to integrate a drying unit seamlessly. The CE certification gave us the confidence to supply to EU-based distributors. Our output has increased by 60%, and syrup consistency is now uniform across batches. The 380V system runs efficiently without power spikes. Highly recommend for any mid-scale producer looking to scale sustainably."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Amina El-Sayed - Date Syrup Startup

"As a solo entrepreneur running a home-based syrup business, I needed something affordable yet professional. I bought the Base Model in June 2025 and have been using it for 4 months. It’s compact, fits perfectly in my garage workspace, and the modular conveyor system makes the process feel industrial without the footprint. Cleaning is a breeze—just mild soap and water, and it looks brand new. I do wish the manual had more visual guides for first-time users, but once I got the hang of it, production became smooth. I’ve already doubled my monthly output and am considering adding a bottling module soon."Purchase Date: June 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Daniel Park - Cafe & Bakery Owner

"We serve house-made date syrup in our cafe and wanted full control over quality. Purchased the Pro Model in January 2025—now 6 months in—and it’s been a game-changer. The fully automatic mode saves us 20 labor hours per week, and the inverter technology keeps energy costs low. The syrup quality is restaurant-grade, and customers consistently praise the rich, natural flavor. The CE certification was essential for our health compliance audit. Setup required a technician, but the long-term efficiency gains are worth it. This system is built to last."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐☆ Omar Ndiaye - Family Farm Operator

"Our farm started producing date syrup as a value-added product last year. We chose the Base Model in April 2024 and have been using it for nearly a year. It’s been solid—stainless steel holds up well even in our humid climate, and the semi-automatic process fits our workforce size perfectly. We especially appreciate the ability to customize processing parameters for our local date variety. The only downside is the 380V requirement—we had to install a dedicated line, which added to initial costs. But now that it’s running, the return on investment is clear. We’re planning to add a packaging module next season."Purchase Date: April 2024 | Usage Period: 11 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Torres - Food Processing Systems Expert

"For small to medium-scale syrup producers, the modular design and CE-certified stainless steel construction of this processing line set a new benchmark. The semi-automatic control system strikes the ideal balance between automation and hands-on quality control—critical for artisanal producers who value batch integrity. I’ve evaluated over 20 syrup lines, and this one stands out for hygiene, scalability, and energy efficiency."

Lena Fischer - Agri-Food Innovation Advisor

"In my work with rural cooperatives, I recommend this line for its adaptability and low barrier to entry. The ability to start with the Base Model and scale to the Advanced or Pro versions makes it financially viable for small farms. The 30% faster reconfiguration time compared to fixed systems is a major operational advantage. It’s a rare blend of industrial reliability and small-business practicality."

Posted: 2 days ago

"Exactly what we needed—compact, CE-certified, and easy to operate. The syrup quality has improved dramatically since switching from manual methods. Customer service helped us choose the right model based on our volume."

Posted: 1 week ago

"After 3 months of use, our labor costs are down and output is up. The modular conveyor is genius—allows us to process different fruits with minor adjustments. Already exploring fig syrup production!"

Posted: 3 weeks ago

"Runs smoothly, cleans easily, and produces beautiful syrup. Only suggestion: include a quick-start video tutorial. Otherwise, extremely satisfied."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.