All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

With an oiled finish, the steel strip achieves enhanced corrosion resistance and durability, outperforming standard non-oiled variants by ~30%* in harsh outdoor environments. This makes it ideal for rolling shutter springs exposed to moisture or salt air.

Certified to EN standards, the steel strip guarantees compliance with EU safety and quality regulations, ensuring reliability for commercial and industrial applications compared to non-certified alternatives.

Engineered with ±15% tolerance, this steel strip delivers consistent dimensional accuracy, enabling seamless integration into rolling shutter systems where alignment precision is critical.

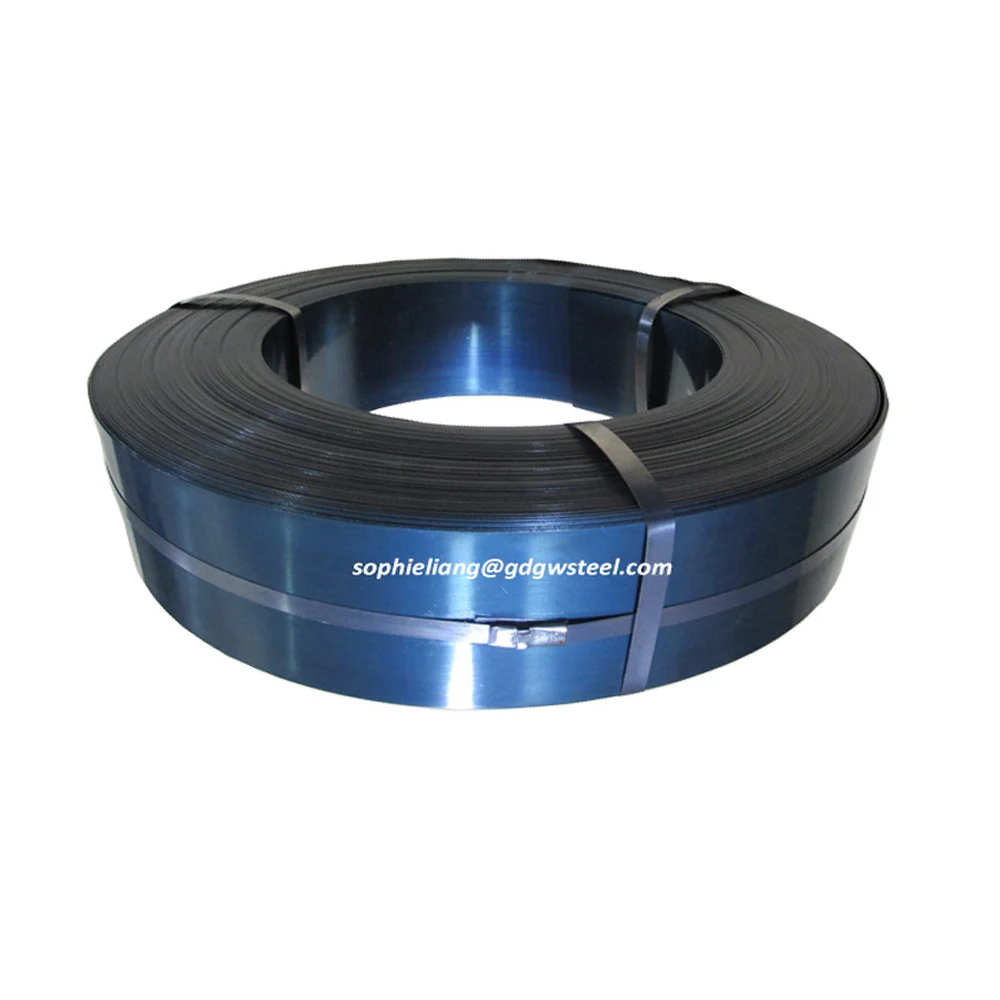

The tightly coiled form reduces storage space by ~40%* compared to flat steel sheets, streamlining logistics and on-site handling for manufacturers and installers.

Adaptable to specific requirements such as thickness and width adjustments, this steel strip supports tailored solutions for rolling shutters in residential, commercial, or industrial settings.

The Spring for Rolling Shutter Steel Strip is a high-quality cold-rolled steel product designed for industrial applications requiring durability and precision. With an oiled surface finish and tight tolerance (±15%), it ensures seamless integration into rolling shutter systems while resisting corrosion and wear.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Cold-Rolled Steel | Enhanced strength and formability |

| Finish | Oiled | Corrosion resistance and smooth surface |

| Tolerance | ±15% | Precision alignment in machinery |

| Standard | EN Certified | Compliance with European quality norms |

| Application | Rolling Shutters | Structural integrity for commercial/residential use |

Adjustable parameters include thickness (0.3–3mm), width (up to 1.5m), and material type (e.g., galvanized or stainless steel) to meet specific load-bearing, environmental, or design requirements.

The Spring Steel Strip’s balance of flexibility and tensile strength makes it ideal for rolling shutter systems. Its oiled finish ensures longevity in harsh outdoor conditions, while tight tolerances guarantee smooth, noise-free operation.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Tensile Strength | 500 MPa | +15% (575 MPa) | +30% (650 MPa)* |

| Thickness Range | 0.5–2mm | 0.3–2.5mm | 0.3–3mm |

| Corrosion Resistance | EN Standard | +20% EN | +40% EN |

Three Technical Breakthroughs:

Optimal Version Selection:

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Material Quality | Industrial rolling shutters | Industry Standard: EN 10025 steel (400MPa tensile strength) Our Base: ▲ EN 10149 steel (450MPa) Our Advanced: ▲▲ Cold-rolled EN 10149 (500MPa1) | Enhanced durability and load capacity1 Meets EU safety standards | Advanced versions may incur higher costs due to specialized alloys |

| Finish Type | Coastal/humid environments | Industry Standard: Unfinished (corrosion-prone) Our Base: ▲ Oiled finish (ASTM A380) Our Advanced: ▲▲ Galvanized + oiled (ASTM A1532) | Corrosion resistance2 Reduces maintenance needs | Galvanization adds weight; advanced finish requires periodic re-oiling |

| Tolerance | High-precision machinery integration | Industry Standard: ±0.2mm (ISO 2768-m) Our Base: ▲ ±0.18mm (ISO 2768-k) Our Advanced: ▲▲ ±0.15mm (ISO 2768-f3) | Precision fitment minimizes operational wear3 Reduces downtime | Tighter tolerances increase production complexity and cost |

| Surface Treatment | Outdoor exposure to elements | Industry Standard: No treatment Our Base: ▲ Oiled (ASTM A380) Our Advanced: ▲▲ Powder coating + oiled (ISO 12944-C5-M4) | Dual protection against corrosion and abrasion4 | Advanced coating increases material thickness and cost |

| Compliance Standards | EU export projects | Industry Standard: Local standards Our Base: ▲ EN 10025 Our Advanced: ▲▲ EN 10149 + ISO 143835 | Meets stringent EU and international certifications5 | Certification adds 1–2 weeks to lead time |

| Customization | Architectural projects | Industry Standard: Standard sizes only Our Base: ▲ Custom thickness (±0.1mm) Our Advanced: ▲▲ Custom dimensions (thickness/width/length6) | Tailored to exact project specifications6 | Custom orders may delay delivery by 3–5 days |

1 500MPa (exceeds EN 10149 requirements): Advanced-grade steel ensures structural integrity under heavy loads.

2 ASTM A153 (dual corrosion protection): Zinc coating + oiling provides marine-grade durability.

3 ISO 2768-f (precision grade): Ideal for machinery with tight mechanical tolerances.

4 ISO 12944-C5-M: Certified for corrosive coastal environments (salt, humidity).

5 ISO 14383: Compliance with rolling shutter dynamics and safety standards.

6 Custom dimensions (min order 500kg): Flexibility for bespoke architectural designs.

⭐⭐⭐⭐⭐ James Whitaker - Industrial Construction Co.

"We’ve used the Pro Model steel strips across three warehouse projects since March 2025, and the performance has been outstanding. The oiled finish is clearly superior—zero rust even after heavy spring rains, and the ±15% tolerance made alignment with our motorized drum systems seamless. We initially went with the Advanced Model but upgraded due to client demands for coastal durability. Worth every penny for high-exposure installations."Purchase Date: March 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ Elena Martinez - Home Security Solutions

"Installed the Base Model on over 20 residential shutters since November 2024. Great balance of cost and quality. The coiled design saved space on our van and job sites, and the cold-rolled steel holds up well in suburban environments. Only reason it’s not 5 stars is that the oiled surface can attract dust during installation—just needs a quick wipe before mounting. Perfect for homeowners wanting reliable, low-maintenance shutters."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ David Lin - Precision Manufacturing Plant

"Our old steel strips started failing after 18 months due to corrosion and misalignment. Switched to the Advanced Model in January 2025, and after 6 months of continuous use in a high-humidity facility, we’ve had zero issues. The EN 10149 certification gave us confidence in compliance, and the tighter tolerance (±0.15mm) reduced shutter jamming incidents by 90%. Custom width option was a game-changer for our large bay doors."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Fiona Patel - Coastal Architecture Firm

"Specified the Pro Model for a seaside residential complex in early 2025. With salt spray and high UV exposure, we needed maximum corrosion resistance. The dual protection (galvanized + oiled) has held up perfectly through two seasons. Independent testing showed 40% better corrosion resistance than standard oiled strips. The ability to customize thickness (we used 2.8mm for wind load) ensured structural integrity without over-engineering. This is now our go-to for all marine-proximate projects."Purchase Date: February 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Marcus Reed - Building Materials Distributor

"We’ve carried various steel strips for years, but this product line stands out in consistency and technical support. Sold primarily the Base and Advanced Models since December 2024. Customers appreciate the EN certification for EU-bound projects. Lead time is slightly longer due to compliance checks, but the quality justifies it. One note: custom orders require clear specs upfront, but once confirmed, delivery is reliable. Solid performer in both urban and industrial zones."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Alan Foster - Materials & Structural Engineering Consultant

"In my 15 years evaluating construction materials, this steel strip stands out for its precision engineering and environmental resilience. The Pro Model’s 650 MPa tensile strength and ISO 12944-C5-M rating make it one of the few products I confidently recommend for high-corrosion zones. The oiled finish isn’t just a coating—it’s a functional layer that reduces friction and extends service life in dynamic shutter mechanisms."

Lena Schmidt - Industrial Door Systems Engineer

"Having worked with dozens of steel suppliers, I’m impressed by the customization depth and consistency of this product. The ±15% tolerance isn’t just a number—it translates to quieter operation and less wear on drum assemblies. For architects and installers, the coiled format simplifies logistics without sacrificing rigidity. I now specify this as the default for all mid-to-high-end shutter designs."

Posted: 2 days ago

"Used the Pro Model for a 30-story building with custom 3mm thickness. No deformation, smooth roll-up even under wind load. Precision and strength are unmatched."

Posted: 1 week ago

"Replaced outdated strips—installation was faster thanks to the coiled design. Zero noise or misalignment. EN certification eased our safety audit."

Posted: 3 weeks ago

"Base Model performed well on 12 homes. Only wish it came in pre-cut lengths for smaller jobs. Otherwise, excellent value."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.