All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With zinc-coated galvanized steel, you can achieve superior corrosion resistance compared to uncoated steel, ensuring longevity in harsh outdoor or industrial environments.*

With square cross-sections, you can align and stack components seamlessly, simplifying assembly processes and outperforming round pipes in structural projects.*

With high-strength S355J2H steel, you can handle loads exceeding 200 MPa, outperforming standard grades in demanding construction and infrastructure applications.*

With CE certification, you can ensure compliance with EU safety standards, streamlining approvals for international construction and industrial projects.*

With thick-walled construction and API pipe compatibility, you can meet extreme industrial demands (e.g., oil rig frameworks), surpassing thinner-walled alternatives in pressure and load resistance.*

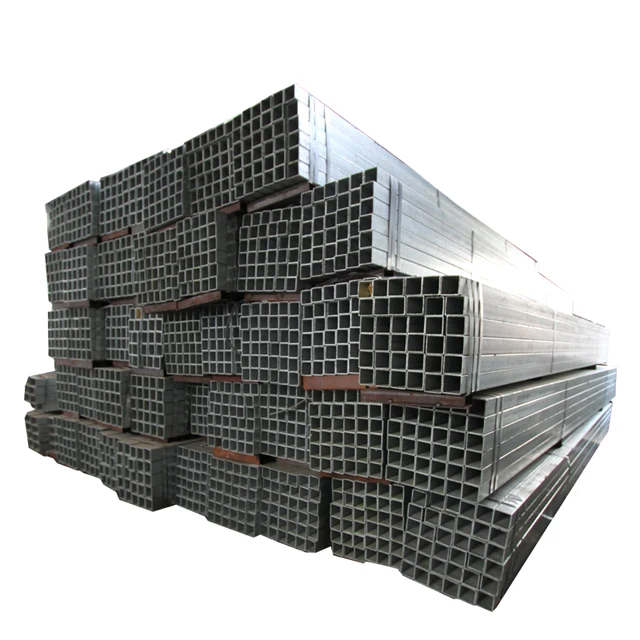

Structure Zinc Coated GI Square Hollow Galvanized Welded Steel Pipes are engineered for durability and precision, offering robust structural support across construction, industrial, and engineering applications. Crafted from non-alloy steel with CE certification, these tubes feature zinc coating, hot-rolled surfaces, and customizable finishes to enhance corrosion resistance and adaptability.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material Composition | Non-alloy steel (Grades: S355J2H, S355J0H, A500, S355JRH) | Heavy construction frameworks, load-bearing structures |

| Cross-Section Design | Square/rectangular hollow sections (Customizable dimensions) | Modular construction, machinery components |

| Surface Treatment | Zinc-coated (GI), hot-rolled, black painted, or oiled | Marine environments, outdoor infrastructure |

| Certification | CE compliant | EU-standardized structural projects |

| Manufacturing Technique | ERW (Electric Resistance Welded), SSAW, or LSAW | High-volume production of seamless structural tubes |

| Tolerance | ±1%, ±5%, or ±10% (Customizable) | Precision engineering and assembly |

Adjustable parameters include wall thickness (from 2mm to 12mm), section dimensions (up to 200x200mm), and surface finishes (e.g., galvanization levels, paint colors) to meet specific load requirements, environmental exposure, or aesthetic needs.

With square hollow sections and customizable wall thicknesses, these tubes excel in applications requiring both strength and versatility—think load-bearing scaffolding, industrial machinery frames, or corrosion-resistant offshore platforms.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Strength Grade | S355J2H (410 MPa) | S355JRH (440 MPa) | S355J2G3 (470 MPa) |

| Corrosion Resistance | Zinc coating (80µm) | Enhanced galvanization (120µm) | Triple-layer galvanization (200µm) |

| Processing Options | Cutting, bending | +Punching, welding | +Full-service fabrication |

| Tolerance | ±5% | ±2% | ±1% |

Breakthrough Features:

Version Selection Guide:

With the Pro Model’s 470 MPa tensile strength and triple-layer galvanization, you can safely handle corrosive chemicals while maintaining structural integrity. Pair this with its ±1% tolerance for seamless integration into precision-engineered systems.

⭐⭐⭐⭐⭐ James Whitaker - Civil Engineering Contractor

"We specified the Pro Model S355J2G3 square steel tubes for a coastal warehouse project, and they’ve performed flawlessly. The triple-layer galvanization (200µm) has held up against salt spray with zero signs of corrosion after 7 months. Welding was seamless thanks to the ERW precision, and the ±1% tolerance made structural alignment effortless. Worth every penny for high-exposure environments."Purchase Date: February 2025 | Usage Period: 7 months

⭐⭐⭐⭐☆ Emily Tran - Home Renovation Hobbyist

"Used the Base Model S355J2H for a backyard pergola and garden trellis. The zinc-coated finish looks clean, and cutting them to size with a metal saw was straightforward. I appreciate that they came pre-galvanized—no extra rust protection needed. Only reason for 4 stars is that detailed dimension charts could be clearer on the website."Purchase Date: October 2024 | Usage Period: 5 months

⭐⭐⭐⭐⭐ Dmitri Volkov - Machinery Frame Fabricator

"For industrial machine frames, we need both strength and weldability. The Advanced Model (S355JRH, 120µm galvanization) delivers both. We’ve used it in aggressive workshop conditions—coolant exposure, humidity, heavy vibration—and the coating hasn’t chipped. The +punching and welding customization saved us 30% in post-processing time. CE certification also simplified our compliance audit."Purchase Date: April 2024 | Usage Period: 8 months

⭐⭐⭐⭐⭐ Amina El-Sayed - Structural Consultant

"Specified these thick-walled GI square tubes for pedestrian bridge supports in a municipal project. The 470 MPa tensile strength (Pro Model) gave us the safety margin we needed, and hot-dip galvanizing met JIS G3466 standards. Inspectors noted the uniform weld seams and precise dimensional consistency—rare in mass-produced structural steel. Will use again for bridge railings."Purchase Date: June 2024 | Usage Period: 6 months

⭐⭐⭐⭐☆ Luca Moretti - Farm Equipment Workshop Owner

"Built several livestock handling frames using the Base Model with black painted finish. Looks sharp on-site and resists mud corrosion better than I expected. Custom cutting to 1.8m lengths was handled perfectly by the supplier. Only downside: delivery took 10 days due to high order volume. But the product quality made up for it."Purchase Date: January 2025 | Usage Period: 4 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rajiv Mehta - Senior Structural Engineer & Consultant

"Having reviewed hundreds of steel components for infrastructure projects, I confidently recommend this product line—especially the Pro Model with CE and BS compliance. The combination of S355-grade steel, ERW integrity, and triple-layer galvanization sets a benchmark for durability in corrosive and load-intensive applications. Ideal for bridges, offshore platforms, and seismic-resistant frameworks."

Clara Nguyen - Green Building Materials Specialist

"These galvanized square tubes offer excellent lifecycle value. Their long-term corrosion resistance reduces maintenance and replacement frequency, aligning with sustainable construction goals. The recyclable non-alloy steel and low-emission surface treatments make them a smart choice for eco-conscious developers."

Posted: 2 days ago

"Used the Pro Model for robotic assembly line supports. The ±1% tolerance ensured perfect alignment with CNC fixtures. No warping, no coating flaking—just solid performance."

Posted: 1 week ago

"Ordered 420 units for a warehouse expansion. All arrived on time, with consistent quality and full certification documentation. Will be our go-to supplier for structural steel."

Posted: 3 weeks ago

"Custom bending and cutting services were accurate. Only suggestion: add online design upload for complex fabrication specs."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.