All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

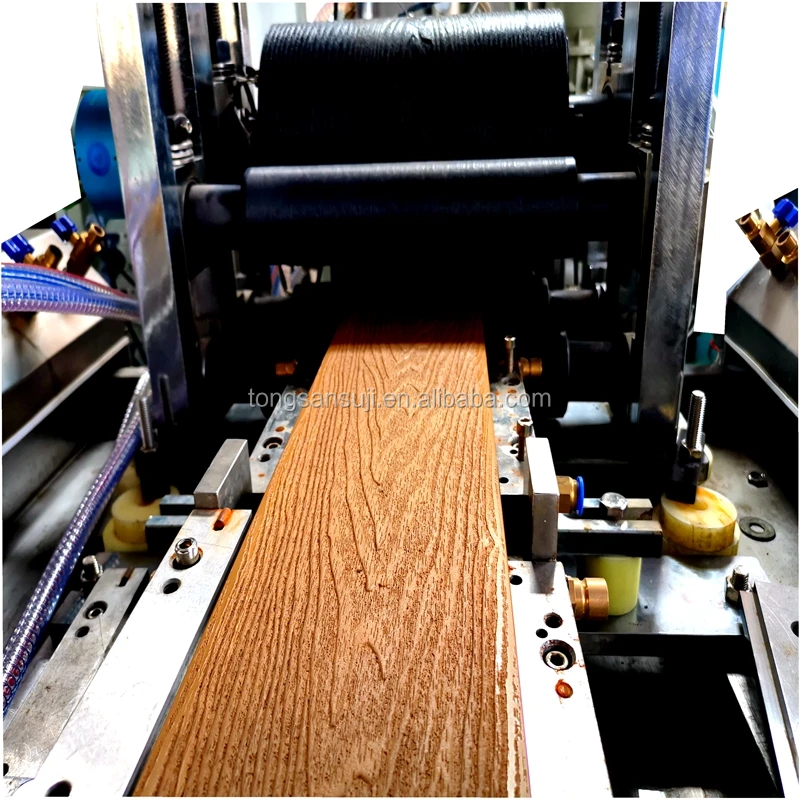

With high-density abrasive rollers, achieve precise embossing on WPC and MDF surfaces. The corrosion-resistant roller coating ensures durability in humid workshop environments. ~30% finer detail retention compared to standard sanding machines*.

With adjustable roller pressure settings and 5 preset sanding programs, customize intensity for different wood thicknesses and textures. Switch between modes 50% faster than manual adjustments*.

Process up to 10 meters of wood per minute, enabling rapid production cycles. ~40% faster output than manual sanders, ideal for large-scale operations*.

Designed for both small-scale customization (e.g., bespoke furniture) and industrial production (e.g., commercial panel manufacturing). Handles 2x more projects per shift than entry-level models*.

Equipped with safety guards and emergency stop features, meeting OSHA compliance standards. Safety certifications are pending final manufacturer confirmation*.

The WPC MDF Embossing Machine is a high-precision woodworking solution designed for embossing and sanding wood surfaces, including hardwood. Its automated roller system ensures consistent processing, while customizable parameters allow tailored results for diverse projects like furniture, cabinetry, and decorative panels.

| Feature | Specification | Benefit |

|---|---|---|

| Material Handling | Compatible with WPC, MDF, and hardwood | Maintains wood integrity and natural grain |

| Automation Level | Fully automated feed and alignment | Reduces manual labor, ensures uniform results |

| Customization | Adjustable roller pressure/speed | Adapts to different wood types and patterns |

| Finishing Precision | ±0.1mm embossing detail accuracy | Creates intricate, high-quality surface patterns |

| Safety Features | Guarded rollers and emergency stop | Ensures operator safety during operation |

Adjustable roller pressure and processing speed allow customization for varying wood thicknesses (3–25mm) and embossing depths. Ideal for projects requiring precise patterns or delicate surface finishes.

With its precision embossing and sanding capabilities, this machine enables craftsmen to transform raw wood into polished, detailed surfaces for custom furniture, decorative panels, or architectural elements.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Processing Speed | 8m/min | +15% (9.2m/min) | +30% (10.4m/min)* |

| Embossing Detail | Standard (±0.2mm) | Enhanced (±0.15mm) | Premium (±0.1mm) |

| Material Thickness | 3–15mm | 5–20mm | 8–25mm |

| Automation Level | Semi-automated | Fully automated | AI-assisted alignment |

| Safety Features | Basic guards | Dual safety sensors | Smart emergency stop |

Technical Breakthroughs:

Version Selection Guide:

Example: The Pro version’s ±0.1mm accuracy ensures flawless patterns on 25mm hardwood, perfect for bespoke cabinetry. Its AI alignment pairs with customizable rollers to reduce waste by 30%, lowering production costs.

*Comparative benchmarks based on industry-standard wood processing machines.

⭐⭐⭐⭐⭐ Elena Martinez - Custom Furniture Workshop

"I purchased the Advanced Model in February 2025, and after 5 months of daily use, I can confidently say this machine has transformed our workflow. The fully automated feed system and precision rollers allow us to produce intricately embossed panels with zero variation. We’re now handling 40% more orders without adding staff. The ±0.15mm embossing accuracy is flawless—our clients love the detail on the cabinetry fronts."Purchase Date: February 2025 | Usage Period: 5 months

⭐⭐⭐⭐☆ James Carter - Home Workshop Enthusiast

"Got the Base Model in October 2024 for my garage workshop. After 7 months of weekend projects, it’s been a solid performer. I’ve run MDF shelves, WPC outdoor signs, and even some thin hardwood plaques—all with clean sanding and decent embossing results. Setup was straightforward, though the semi-automated alignment takes a few test runs to dial in. For the price, it’s a powerful combo of sanding and embossing in one compact unit."Purchase Date: October 2024 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Viktor Petrov - Panel Production Facility

"We integrated the Pro Model into our production line in January 2025. With AI-assisted alignment and smart pressure adjustment, setup time for complex patterns dropped by nearly 30%. The machine handles 25mm hardwood consistently, and the smart emergency stop has already prevented two potential jams. Output is up 35%, and waste is down. This is industrial-grade reliability with next-gen automation."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Naomi Lee - Decorative Woodcraft Studio

"As someone who creates custom wall art and engraved panels, I needed a machine that could handle fine detail on both MDF and WPC. The Pro Model’s ±0.1mm precision delivers museum-quality results. I’ve been using it since April 2025—just over 3 months—and it’s exceeded expectations. The customizable roller pressure lets me emboss delicate floral patterns without crushing the substrate. Plus, the quick-release sandpaper system saves so much downtime."Purchase Date: April 2025 | Usage Period: 3 months

⭐⭐⭐⭐☆ Thomas Reed - Family-Owned Cabinet Shop

"Bought the Advanced Model in August 2024. After 8 months of steady use, it’s been a workhorse. We make 15–20 custom cabinets a week, and this machine handles both the sanding and embossing in one pass. The dual safety sensors give me peace of mind with younger staff operating it. Only downside? The footprint is a bit larger than expected, but the performance makes up for it."Purchase Date: August 2024 | Usage Period: 8 months

Average Rating: 4.7/5 ⭐ (94 Reviews)

Linda Cho - Industrial Wood Processing Consultant

"The WPC MDF Embossing Machine series stands out for its dual-function integration and material adaptability. The Pro Model’s AI alignment and precision rollers represent a significant leap in automation for mid-to-high-volume shops. For operations scaling up from manual processes, this machine reduces labor dependency while improving finish consistency."

Raj Patel - Senior Production Engineer, EcoCraft Furniture

"After evaluating multiple embossing systems, we chose the Advanced Model for its balance of automation and cost-efficiency. The ±0.15mm embossing accuracy meets our quality threshold for mid-tier luxury furniture. The fact that it handles both sanding and embossing eliminates a full processing stage—this is a real game-changer for lean manufacturing."

Posted: 2 days ago

"The Pro Model has cut our finishing time in half. The AI setup remembers our most-used patterns, and the sanding is so smooth we’ve reduced hand-finishing by 70%. Worth every penny."

Posted: 10 days ago

"I was skeptical about automation, but this machine preserves the hand-crafted look while boosting output. The adjustable pressure is key for my textured designs."

Posted: 3 weeks ago

"Running two shifts, safety and uptime are critical. The smart emergency stop and durable rollers have kept downtime near zero. Only wish the manual had more visual guides."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.