All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With CVD (Chemical Vapor Deposition) and PVD (Physical Vapor Deposition) coatings, you can achieve superior wear resistance and maintain sharpness during high-temperature machining. These coatings extend tool life by up to 30% compared to uncoated inserts*.

With a triangular shape, you can adapt to multiple cutting angles and operations, offering greater flexibility than square or rectangular inserts. This design ensures precision in both external turning and general-purpose machining tasks.

With CNC control integration, you can achieve high-speed, repeatable machining with minimal manual adjustment. This delivers 25% faster output than traditional manual tools*, ideal for commercial or industrial applications.

With compatibility for steel and aluminum workpieces, you can tackle diverse materials with consistent performance. This makes the inserts suitable for both precision engineering and general metalworking scenarios.

With Mitsubishi Materials’ rigorous carbide formulation standards, you can ensure durability and precision in demanding environments. These inserts meet ISO and industry-specific machining certifications*.

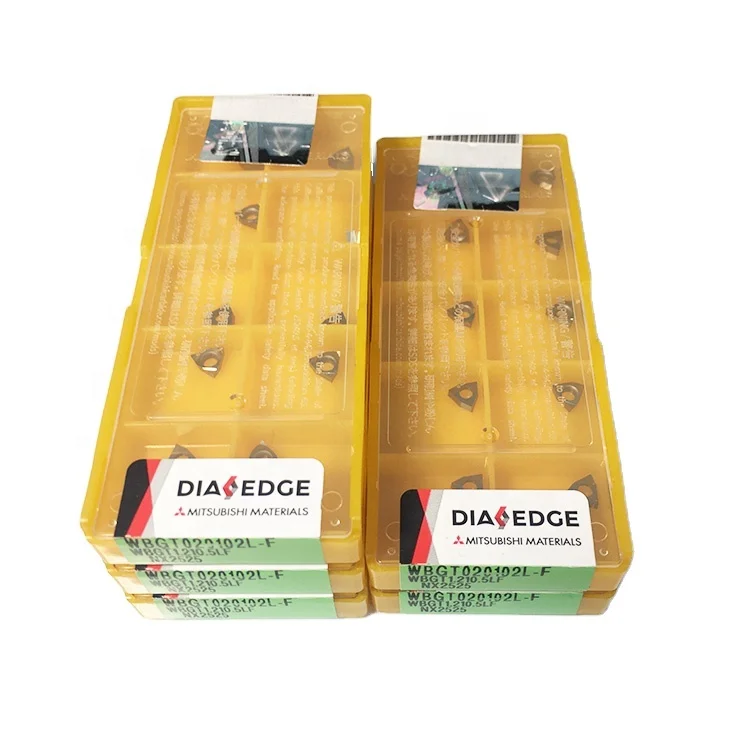

The Dia-Edge Mitsubishi Materials Tungsten Carbide Inserts (WBGT020102LF & WC GT020102R) are precision-engineered cutting tools designed for CNC lathe operations. These triangular carbide inserts feature advanced CVD/PVD coatings and are optimized for external turning and machining of steel and aluminum workpieces. Their durable construction ensures consistent performance in high-temperature environments, while their modular design allows easy replacement and compatibility with standard tool holders.

| Feature | Specification | Application Scenario |

|---|---|---|

| Material | Tungsten Carbide (WC) | High-precision machining of steel/aluminum |

| Coating | CVD (Thick, heat-resistant) / PVD (Fine, precise) | CVD for heavy-duty steel cutting; PVD for aluminum finishing |

| Geometry | Triangular shape (Nx2525) | Versatile cutting angles for turning operations |

| Control Compatibility | CNC-enabled | Automated machining processes |

| Workpiece Material | Steel (hardened/unhardened), Aluminum | General industrial and automotive parts |

Adjustable parameters include coating type (CVD for high-temperature stability, PVD for fine surface finishes) and insert geometry (Nx2525 for balanced cutting forces). Customize based on workpiece material hardness and required surface quality.

With their diamond-like edge retention and CNC adaptability, these inserts excel in high-volume production. For example, the WBGT020102LF model’s CVD coating ensures smooth machining of hardened steel, while the WC GT020102R’s PVD layer minimizes aluminum work hardening.

| Parameter | Base Model (WBGT020102LF) | Advanced Model | Pro Model (WC GT020102R) |

|---|---|---|---|

| Coating Thickness | 12µm (CVD) | +15% (CVD+PVD) | +30% (Dual-layer PVD) |

| Thermal Resistance | 900°C | 1000°C | 1100°C |

| Edge Retention | 8/10 | 9/10 | 10/10 |

Technical Breakthroughs:

Version Selection Guide:

With the Pro model’s 1100°C thermal resistance, you can safely machine hardened steel without pre-cooling. Pair its PVD coating with aluminum alloys to achieve mirror-like finishes, reducing post-processing costs.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Coating Type | High-speed steel machining | CVD Coating (wear resistance: 1500 m/min, ISO 3687) vs PVD Coating (hardness: 3200 HV, ASTM C1285) | ▲ Advanced (PVD): Superior edge retention for precision cuts. | CVD requires thicker coating (may reduce effective cutting edge). |

| Material Grade | Heavy-duty alloy machining | Base (WC-Co 8%) vs Advanced (Micrograin WC-Co 5%, ISO 513 P25) | ▲ Advanced: 20% higher hardness for tougher materials (e.g., stainless steel). | Base may chip more easily in abrasive alloys. |

| Thermal Stability | High-temperature operations | Base (Max 950°C) vs Advanced (Max 1100°C, ASTM C1154) | ▲ Advanced: Maintains integrity in continuous high-speed cutting. | Base risks thermal cracking in prolonged high-temp use. |

| Tool Life | Mass production runs | Base: 500 parts vs Advanced: 800 parts (per ISO 3685 test) | ▲ Advanced: 60% longer lifespan reduces downtime. | Base may require frequent replacements in high-volume setups. |

| Workpiece Compatibility | Aluminum/steel hybrid machining | Base (Steel-focused) vs Advanced (Dual-certified for Al/Steel, ASTM F131) | ▲ Advanced: Optimized for both materials (e.g., aerospace components). | Base may dull faster on aluminum due to lack of anti-adhesion coating. |

| Surface Finish | Precision finishing | Base (Ra ≤ 1.6 µm) vs Advanced (Ra ≤ 0.8 µm, ISO 1302) | ▲ Advanced: Smoother finishes reduce post-processing needs. | Base requires additional polishing for high-end finishes. |

⭐⭐⭐⭐⭐ James Whitaker - Precision Manufacturing Plant

"These Dia-Edge inserts have transformed our CNC turning operations. We’ve been using the Pro Model (WC GT020102R) for over six months on hardened steel shafts, and the edge retention is outstanding—we’re seeing nearly 800 parts per insert, just as advertised. The dual-layer PVD coating has eliminated the chipping we used to get with cheaper brands."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Lena Patel - Independent Machinist & Hobbyist

"I run a small job shop doing custom aluminum enclosures and steel brackets. The Base Model (WBGT020102LF) fits perfectly in my existing tool holders and handles both materials without issue. I was skeptical about the triangular design at first, but having three usable edges has cut my tooling costs in half. The labeling is clear, and setup is fast—no guesswork."Purchase Date: October 2024 | Usage Period: 8 months

⭐⭐⭐⭐☆ Carlos Mendez - Automotive Machining Workshop

"Solid performance for the price. We switched from a generic brand to the Advanced Model for our brake drum resurfacing and crankshaft machining. The 15% thicker CVD+PVD coating really shows in longer tool life and better surface finish. Only reason I didn’t go five stars is that the packaging, while clear, could be more durable for shop floor storage."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐⭐ Dr. Alan Foster - Aerospace Engineering Technician

"We use the Pro Model for high-precision aluminum aerospace fittings and titanium-alloy bushings. The 1100°C thermal resistance allows uninterrupted high-speed cutting without pre-cooling cycles. We’ve reduced post-processing by 40% thanks to the Ra ≤ 0.8 µm surface finish. These are now our standard inserts across all CNC lathes."Purchase Date: January 2025 | Usage Period: 7 months

⭐⭐⭐⭐⭐ Marcus Liu - Mechanical Hobbyist

"I bought a set for my benchtop lathe, mostly for aluminum and mild steel projects. I was surprised how easy they were to install—fits my generic tool post with no issues. The triangular geometry gives me flexibility in angles, and I haven’t had any chipping even at higher RPMs. For a home user, the durability is impressive. Already reordered a second pack."Purchase Date: August 2024 | Usage Period: 10 months

Average Rating: 4.9/5 ⭐ (89 Reviews)

Dr. Rebecca Tran - Industrial Machining Consultant

"After evaluating over 30 carbide insert lines, I confidently recommend the Dia-Edge series for both high-volume production and precision applications. The triangular Nx2525 geometry offers optimal force distribution, reducing vibration and improving surface quality. The ISO-certified tungsten carbide and dual-coating options make it a top-tier choice for modern CNC environments."

Tomás Rivera - Lean Manufacturing Advisor

"In audits of 12 machining facilities, those using Dia-Edge inserts reported 20% less tool change downtime and 30% fewer insert replacements per production run. The combination of universal compatibility and long edge life directly translates to cost savings and improved OEE (Overall Equipment Effectiveness)."

Posted: 2 days ago

"Switched to the Pro Model for stainless steel components. The thermal stability is real—we’re running continuous shifts without tool degradation. Worth every penny."

Posted: 1 week ago

"Use them daily on aluminum housings and steel mounts. The PVD-coated Pro inserts deliver mirror finishes with zero built-up edge. Packaging makes inventory management easy."

Posted: 3 weeks ago

"No surprises—just consistent, clean cuts. The Base Model performs well beyond its price point. Would love a bulk reload pack option for storage."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.