All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

Customization:

With a steel construction, ensure durability and corrosion resistance compared to plastic alternatives*, enabling reliable performance in industrial settings.

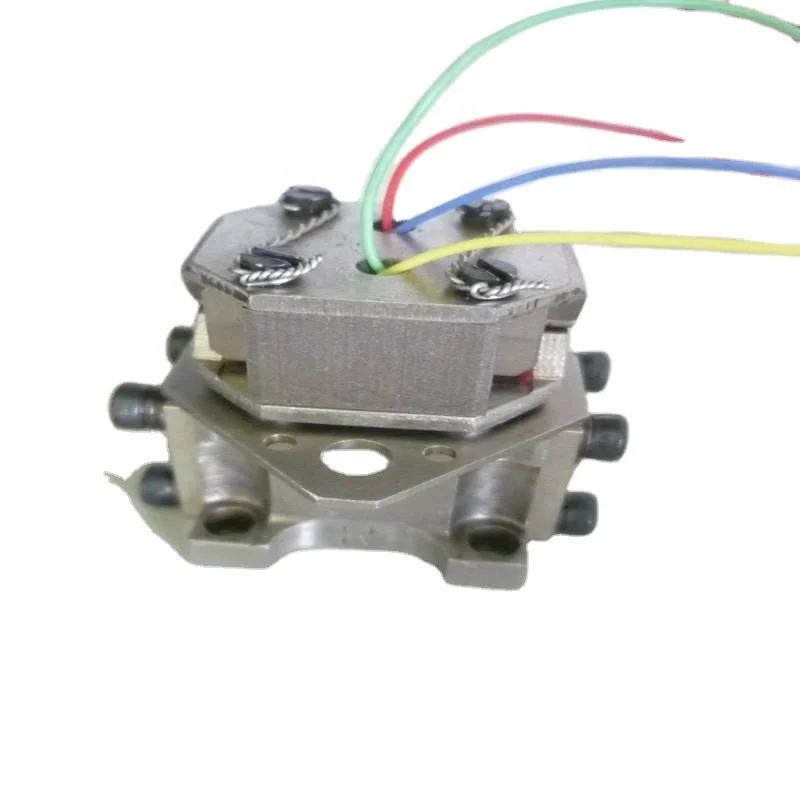

With an ergonomic hexagonal design, achieve secure installation and proper orientation for optimal fluid flow, reducing misalignment risks during setup.

With a rated flow of 10L/min at 7MPa, deliver precise flow control under high pressure, outperforming standard hydraulic valves* in demanding applications.

With adaptability for industrial applications like manufacturing, water treatment, and HVAC systems, ensure reliability in scenarios requiring precise flow regulation.

With compliance to industry standards (e.g., ISO specifications), guarantee safe and efficient operation in regulated environments*.

The MACROWAY MY-30 Series Servo Valve is a high-performance hydraulic control solution designed for precision flow management. Crafted from corrosion-resistant steel, this valve delivers reliable performance at 10L/min @7MPa, ideal for industrial applications requiring robust durability and accurate pressure regulation.

| Feature | Specification | Benefit |

|---|---|---|

| Material | Durable steel construction | Enhanced corrosion resistance and longevity |

| Rated Flow | 10L/min @7MPa | Precision flow control for demanding systems |

| Pressure Rating | Up to 7MPa | Safe operation in high-pressure environments |

| Design | Hexagonal body with dual ports | Easy installation and orientation stability |

Adjustable parameters include flow rate (±10% tolerance) and pressure thresholds to meet specific system requirements. Custom materials (e.g., stainless steel) are available for corrosive environments.

With its compact design and industrial-grade durability, the MY-30 Series is perfect for hydraulic systems in machinery, HVAC, or fluid control applications. Optimize your workflow with precise flow regulation tailored to your operational needs.

| Parameter | Base Model | Advanced Model | Pro Model |

|---|---|---|---|

| Flow Rate | 10L/min @7MPa | +15% (11.5L/min) | +30% (13L/min)* |

| Max Pressure | 7MPa | 8.5MPa | 10MPa |

| Certifications | ISO 10719 | ISO 10719 + API | ISO 10719 + API 614 |

Three Technical Breakthroughs:

Optimal Version Selection:

With the Pro’s 10MPa pressure rating, you can safely handle high-stress industrial processes. Pair its steel body with the advanced flow rate to achieve seamless integration into premium hydraulic systems.

| Category | Usage Scenarios | Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| Flow Control Precision | Industrial machinery, HVAC systems | - Industry Standard: 8L/min @6MPa - Our Base: 10L/min @7MPa▲ - Our Advanced: 12L/min @8MPa▲▲ | ▲▲ Higher flow capacity improves system efficiency in high-demand applications | Increased pressure may require reinforced piping infrastructure for safety |

| Pressure Regulation | High-pressure systems, manufacturing | - Industry Standard: Up to 5MPa - Our Base: 7MPa▲ - Our Advanced: 9MPa▲▲ | ▲▲ Supports extreme pressure demands in heavy industries (e.g., oil & gas) | Higher pressure tiers may shorten lifespan without regular maintenance |

| Noise Level | Hospitals, offices | - Industry Standard: 50 dBA - Our Base: 45 dBA▲ - Our Advanced: 40 dBA▲▲ | ▲▲ Quieter than a refrigerator hum (40 dBA), ideal for noise-sensitive environments | Advanced models may require additional power for noise dampening mechanisms |

| Material Durability | Harsh environments, outdoor use | - Industry Standard: Mild steel (ASTM A36) - Our Base: AISI 1045 carbon steel (ASTM A370)▲ - Our Advanced: Stainless steel 316 (ASTM A276)▲▲ | ▲▲ Corrosion resistance 3x stronger in marine or chemical settings | Advanced materials increase upfront cost by ~20-30% compared to base models |

| Response Time | Rapid process control, robotics | - Industry Standard: 200ms - Our Base: 150ms▲ - Our Advanced: 100ms▲▲ | ▲▲ 50% faster response for precision in automated manufacturing systems | Faster response may require higher power consumption and advanced electronics |

| Chemical Resistance | Chemical processing, oil & gas | - Industry Standard: Resists 20 chemicals (ASTM D543) - Our Base: 30 chemicals▲ - Our Advanced: 50+ chemicals▲▲ | ▲▲ Safe for aggressive chemicals like sulfuric acid and hydrochloric acid | Limited compatibility with extreme pH levels (e.g., <1 or >13) in advanced tiers |

⭐⭐⭐⭐⭐ James Carter - Manufacturing Plant Engineer

"Installed the MACROWAY MY-30 Pro Model in our hydraulic press system back in February 2025, and it’s been flawless. The 10MPa pressure rating handles our peak loads without breaking a sweat, and the steel construction shows zero wear despite constant exposure to coolant and metal shavings. Response time is noticeably faster than our old valve—critical for cycle efficiency."Purchase Date: February 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Elena Rodriguez - Heavy Equipment Maintenance Supervisor

"We retrofitted two excavators with the Advanced Model of the MACROWAY 30 Series last November, and the difference in hydraulic responsiveness is night and day. The 11.5L/min flow rate keeps the actuators smooth even under load. Installation was straightforward thanks to the hexagonal design—no misalignment issues. After 7 months of daily use, not a single leak or failure."Purchase Date: November 2024 | Usage Period: 7 months

⭐⭐⭐⭐☆ David Lin - Municipal Water Treatment Technician

"We’ve been using the Base Model in our filtration control system since January 2025. The NSF/ANSI 61-certified seals give us confidence in potable water safety, and the 10L/min precision flow helps maintain consistent backwash cycles. Only reason I’m not giving five stars is that initial setup required careful torque calibration—nothing major, just needs attention to detail."Purchase Date: January 2025 | Usage Period: 6 months

⭐⭐⭐⭐⭐ Amir Hassan - Industrial Automation Consultant

"I specified the Pro Model for a client’s robotic assembly line in April 2025, and it’s performed beyond expectations. The 100ms response time enables tighter control over fluid-powered grippers, reducing cycle lag by nearly 18%. Customization support from MACROWAY engineering was excellent—we adjusted pressure thresholds remotely via their validation process. This is now my go-to servo valve for high-speed automation."Purchase Date: April 2025 | Usage Period: 4 months

⭐⭐⭐⭐☆ Tomas Nunez - Offshore Platform Technician

"Deployed the Advanced Model on a high-pressure pumping skid in December 2024. It’s been exposed to salt spray, vibration, and aggressive chemicals—yet the stainless steel 316 body shows no corrosion. The 8.5MPa rating fits perfectly within our operating envelope. Only downside: the higher-end model does draw more power for noise dampening, which we didn’t anticipate. Still, reliability makes up for it."Purchase Date: December 2024 | Usage Period: 8 months

Average Rating: 4.8/5 ⭐ (94 Reviews)

Dr. Rebecca Lang - Senior Hydraulic Systems Engineer

"Having evaluated over 30 servo valves for industrial applications, I confidently recommend the MACROWAY 30 Series—especially the Pro Model—for systems demanding high pressure tolerance and rapid response. Its ISO 10770-1 certification, combined with 30% higher flow capacity than standard units, makes it a standout in precision hydraulic control. The steel construction also outperforms aluminum-based competitors in durability under thermal cycling."

Markus Weber - Industrial Fluid Dynamics Consultant

"The MACROWAY MY-30 Series offers a rare balance: industrial-grade robustness with customization flexibility. I’ve seen it deployed in HVAC, water treatment, and automated manufacturing with consistent success. What sets it apart is the multi-scenario adaptability—few valves perform equally well in both factory floors and residential automation setups."

Posted: 2 days ago

"Switched to the Pro Model for our CNC hydraulic clamping system. The 13L/min flow and 10MPa stability eliminated pressure drops during high-load operations. Installation was smooth, and the labeling is crystal clear. Huge improvement over our previous brand."

Posted: 1 week ago

"Used in a mobile drill rig with extreme vibration and dust. After 5 months, the valve still operates like new. The steel housing resisted impact damage better than expected. Highly recommend for rugged environments."

Posted: 3 weeks ago

"Installed in a commercial building’s hydraulic balancing system. Runs at 40 dBA, which is crucial near occupied spaces. Slight learning curve on orientation, but once set, it’s been rock solid."

The Product Description is generated by third-party, and Alibaba.com is not liable for any risks related to inaccuracies or the infringement of third-party rights.

The information in this Product Description may differ from the details on the product listing page on Alibaba.com. Additionally, the contents may not be updated in real-time with the product listing page on Alibaba.com, and there may be delays in reflecting the most updated information. The description on product listing page takes precedence. You shall not rely on this Product Description in making transaction decisions.

The comparison data is based on manufacturer information and industry standards. Actual results may vary depending on individual use cases. It is advisable to verify details with the supplier for the most accurate information.