Popular in your industry

Top categories

About 168t injection molding machine

Introduction to 168t Injection Molding Machines

Injection molding machines are pivotal in the manufacturing sector, with the 168t injection molding machine standing as a notable example. This category of machinery is engineered for precision and designed to meet the diverse needs of various industries. The 168-ton class specifically refers to the clamping force of the machine, making it suitable for a wide range of plastic molding applications.

Technical Specifications and Applications

The 168t injection molding machine is equipped with advanced features that cater to efficient production processes. These machines are capable of handling various materials with precision, making them suitable for creating components in sectors such as consumer electronics, pharmaceuticals, food and beverage, and automotive. The adaptability of these machines allows for their application in producing intricate designs, from PVC pipe fittings to thin-wall containers and automotive parts.

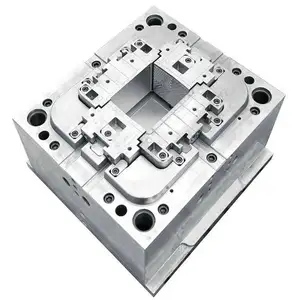

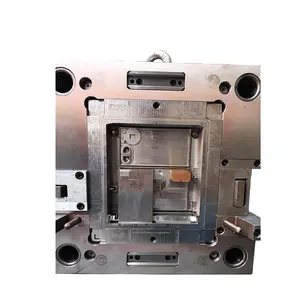

Design and Material Considerations

Design enhancements in injection molding equipment ensure high-speed operation and longevity. The machines incorporate a special screw design that optimizes plasticizing capacity, enhancing shot weight and speed. Materials used in the construction of these machines, such as the steel bush in the clamping unit, are selected to minimize wear and reduce lubrication requirements, thereby potentially lowering operational costs.

Features and Advantages

A plastic injection molder like the 168t is designed for durability and a long service life. The integration of a single-cylinder system with a servo-valve ensures a responsive operation. With clamping forces ranging from 2,000 kN to 13,000 kN, these machines are built to withstand significant machining forces. The precise clamping force is a testament to the machine's ability to produce consistent and accurate molded parts.

Efficiency and Sustainability

Efficiency in molding processes is paramount, and the plastic injection moulding machine is a testament to this principle. The equipment's special design not only increases productivity but also aims at reducing the environmental impact by minimizing waste and the use of lubricants. This approach aligns with the growing need for sustainable production practices across industries.

Choosing the Right Machine

Selecting the appropriate injection molding machinery is crucial for any plastic processing business. The 168t machines on Alibaba.com are presented by various wholesalers, allowing buyers to find a machine that fits their specific molding requirements. These machines transform plastic granules into precise dimensions, ensuring improved accuracy for your applications.