Introduction to 1Ton Melting Furnaces

Industrial melting furnaces are pivotal in metallurgical processes, particularly the 1ton melting furnace, a versatile unit designed for the smelting of various metals. These furnaces serve a critical role in the transformation of scrap metals into usable forms, facilitating the production of diverse steel types from iron, as well as the melting of non-ferrous metals like aluminum and copper.

Types and Applications

The application of industrial melting furnaces spans across numerous sectors, from jewelry crafting, utilizing smaller-scale furnaces for precious metals like gold and silver, to large-scale industrial operations that handle metals up to 20 tons. The versatility of these furnaces is evident in their ability to accommodate different melting requirements, whether for intricate components or substantial metal structures.

Technical Features and Materials

Industrial furnaces are engineered to operate efficiently within a power range of 380v to 950v, with working power capabilities stretching from 180kw to 2,000kw. The construction of these furnaces incorporates large capacitor banks, ensuring current stabilization, and is complemented by robust insulation to prevent any potential hazards from water contact. Furthermore, safety mechanisms, such as circuit breakers, are integral to these systems, providing automatic shutdown in fault conditions.

Advantages of Using a 1Ton Melting Furnace

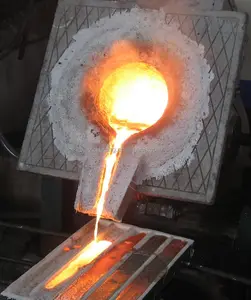

The metal melting furnace is designed to reach temperatures between 2,100 to 1,750 degrees Celsius, efficiently melting a wide range of metals. With melting speeds varying based on metal type and furnace specifications, these units can typically complete a melting cycle within 40 to 60 minutes. Additionally, the tilting mechanism of the melting pots, capable of reaching up to 95 degrees, ensures complete and controlled pouring of molten metal.

Innovative Cooling and Control Systems

Each 1ton induction furnace is equipped with a water-cooling system to manage the high temperatures involved in the melting process. Operation is streamlined through the use of a PLC system, which allows for precise control over the melting process. The integration of electrical induction systems for heating and hydraulic pressure systems for tilting further enhances the functionality and efficiency of these furnaces.

Choosing the Right Melting Furnace

Selecting an appropriate steel melting furnace is crucial for meeting specific industrial needs. While Alibaba.com does not manufacture or sell these products directly, the platform hosts a vast array of suppliers offering furnaces that cater to both large-scale and smaller operations. Prospective buyers can explore a multitude of options, ensuring they find a melting solution that aligns with their operational requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4