Popular in your industry

Top categories

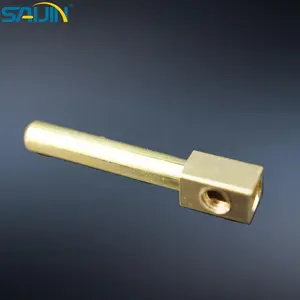

About 2 pin plug mould

Introduction to 2 Pin Plug Moulds

The realm of electrical fittings is vast and complex, with the 2 pin plug mould standing as a cornerstone in the manufacturing of electrical connectors. These moulds are the foundational tools used to create the ubiquitous 2 pin plugs, essential for powering a myriad of devices. In this detailed overview, we delve into the intricacies of 2 pin plug moulds, exploring their types, applications, features, and the materials commonly used in their construction.

Types and Applications

Injection moulding is a primary method for producing 2 pin plugs, where precision and durability are paramount. The types of moulds vary, catering to different production requirements, from small-scale operations to large-volume manufacturing. The application of these moulds extends beyond mere functionality; they are also employed in creating decorative elements such as bolection moulds, which enhance the aesthetic appeal of various products.

Features and Design Considerations

When selecting a 2 pin plug injection mould, several features must be considered. The design intricacies include the ease of ejection, cooling system efficiency, and the robustness of the mould to withstand repeated use. Moulds are designed to be compatible with various injection moulding machines, ensuring seamless integration into existing production lines. Additionally, standardization of components like lift bars and clamp slots can be a focus to streamline the manufacturing process.

Material Selection

Material choice is critical in mould making, influencing the longevity and quality of the final product. Options range from hardened steel to aluminum, each offering distinct advantages. The selection is based on the required finish, the expected production volume, and the complexity of the plug design. While iron moulds are common, alternative materials are also available to meet specific moulding needs.

Advantages of Quality Moulds

A well-crafted 2 pin plug mould brings numerous advantages to the production line. It ensures consistent quality in plug manufacturing and can reduce overall production costs by minimizing waste and optimizing cycle times. The right mould can also enhance the longevity of the plugs produced, ensuring that they meet the necessary safety and functionality standards.

Choosing the Right Mould on Alibaba.com

Alibaba.com serves as a bridge between businesses, offering a diverse selection of 2 pin plug moulds to meet various production demands. The platform facilitates connections with experienced suppliers who can provide moulds tailored to specific requirements. Prospective buyers can leverage the wealth of information available on the site to make informed decisions about their mould fabrication needs.