Popular in your industry

Related Searches:

Top categories

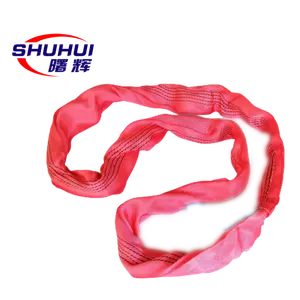

About 30 ton nylon lifting sling belt

Introduction to Lifting Slings

Lifting slings are an essential component in material handling sectors, designed to move heavy loads safely and efficiently. Among the various types, the 30 ton nylon lifting sling belt stands out for its combination of strength, flexibility, and durability. This introduction delves into the specifics of nylon lifting sling belts, highlighting their applications and features.

Types and Applications

Lifting slings come in multiple forms, each suited to particular tasks. The heavy-duty lifting sling is ideal for industrial applications, while the industrial lifting sling caters to rigorous daily operations. The nylon webbing sling is particularly useful for delicate surfaces due to its soft texture, preventing damage to the load. These slings are employed in construction, shipping, and logistics, demonstrating versatility across various industries.

Features of Nylon Lifting Slings

The 30 ton nylon lifting sling belt is engineered for balance and security. Its synthetic material offers excellent resistance to abrasion, ensuring longevity even under strenuous conditions. The flexibility of a nylon bridle sling allows for snug and secure encapsulation of irregularly shaped loads, while the adjustable lifting sling provides adaptability for different sizes and weights, enhancing its utility.

Material and Advantages

Nylon, as a material for lifting slings, presents numerous advantages. It is inherently resilient against moisture and chemicals, making the nylon crane sling a reliable choice in adverse environments. The elasticity of nylon reduces shock loading issues, and its non-conductive nature ensures safer operations where electrical hazards are present. Moreover, the nylon rigging sling is lightweight, easing the handling process for operators.

Selection Considerations

When selecting a 30 ton nylon lifting sling belt, it is crucial to assess the weight and nature of the load, frequency of use, and the lifting environment. Factors such as temperature, humidity, and potential exposure to corrosive elements are critical in determining the appropriate sling. The right choice ensures not only the longevity of the sling but also the safety of the lifting operation.

Conclusion

In conclusion, the 30 ton nylon lifting sling belt is a pivotal tool for heavy lifting tasks. Its material properties and design cater to a broad range of applications, ensuring efficient and secure handling of loads. Prospective buyers are encouraged to consider the outlined factors to make an informed selection suitable for their specific lifting requirements.