Introduction to 360 Degree Rotary Actuators

360 degree rotary actuators are pivotal components in modern industrial automation, offering precise rotational motion control. These devices are engineered to provide a full 360-degree range of motion, making them versatile for various applications. The actuator's design allows for rotation in multiple planes, facilitating complex movements for machinery and equipment.

Types and Variations

Rotary electric actuator models and pneumatic rotary actuators are common types within this category. Each type is tailored for specific operational environments, with electric versions being ideal for precise control and pneumatic options favored for their rapid response and high-force capabilities. Additionally, hydraulic rotary actuators offer robust performance in heavy-duty applications.

Applications and Uses

The application of 360 degree rotary actuators spans numerous industries, from manufacturing to aerospace. They are integral in equipment such as automated assembly lines, robotics, and valve operations. Their adaptability makes them suitable for tasks that require both accuracy and the ability to withstand high torque demands.

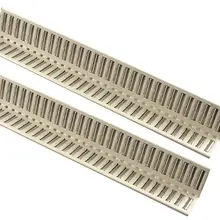

Features and Materials

A compact rotary actuator is designed with durability in mind, often constructed from materials like stainless steel or aluminum to resist corrosion and wear. Features may include integrated sensors for position feedback, which are essential for synchronizing movements in complex automation systems.

Advantages of Using Rotary Actuators

The advantages of using a 360 degree rotary actuator include improved precision in motion control, enhanced efficiency in operation, and the ability to operate in tight spaces due to their compact design. Their reliability and durability also make them a preferred choice for continuous operation in industrial settings.

Selection Considerations

When selecting a rotary actuator, it is crucial to consider factors such as torque requirements, the speed of operation, and compatibility with existing systems. The actuator's environmental resistance, such as its ability to operate under extreme temperatures or in corrosive environments, is also an important consideration.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4