Popular in your industry

Top categories

About 50mm2 silicon rubber cable

Introduction to 50mm2 Silicon Rubber Cable

The 50mm2 silicon rubber cable is a specialized type of electrical wire designed for a variety of applications where durability and heat resistance are paramount. This category of cable is particularly suited for environments that require robust and flexible wiring solutions.

Types and Applications

Silicon rubber cables come in various types, each tailored to specific applications. The 50mm2 size is commonly used in industries where high currents are needed, such as in power distribution, heavy machinery, and renewable energy sectors. Its flexibility makes it ideal for installations that require wiring to bend around tight corners or within confined spaces.

Features and Materials

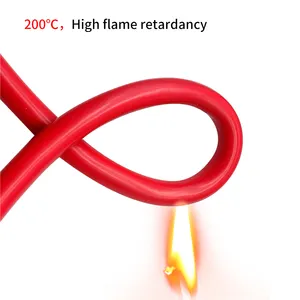

The core feature of the silicon insulated cable is its insulation material. Silicon rubber provides excellent thermal stability and can withstand a wide range of temperatures, making it suitable for harsh environments. The 50mm2 dimension refers to the cross-sectional area, offering a balance between electrical conductivity and physical robustness.

Advantages of Silicon Rubber Insulation

Silicon rubber insulated cables, such as the 50mm2 variant, offer significant advantages. They are highly resistant to thermal extremes, chemicals, and UV exposure. This resilience translates to a longer lifespan and reliable performance in challenging conditions.

Comparing Insulation and Conductivity

When selecting a silicon rubber insulated wire, it's crucial to consider both the insulation quality and the conductivity needs. The 50mm2 cable provides a substantial conductive core, typically made of copper or aluminum, encased in high-grade silicon rubber for optimal insulation.

Choosing the Right Cable for Your Needs

In sourcing a 50mm2 cable, it's important to assess the specific requirements of your project. Factors such as the operating environment, current-carrying capacity, and the need for flexibility should guide your selection process, ensuring that the cable meets your application's demands.