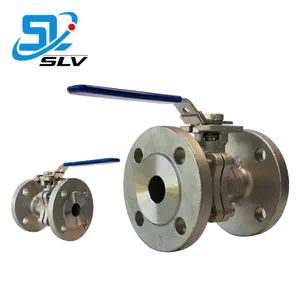

Introduction to A216 WCB Ball Valves

Ball valves are a crucial component in managing the flow and pressure within piping systems, and the A216 WCB ball valve is a prominent category known for its robustness and versatility. This type of valve is designed to meet various industrial requirements, ensuring a reliable solution for fluid control. The A216 specification denotes the material quality, with WCB indicating a cast carbon steel build, suitable for a wide range of temperatures and pressures.

Types and Applications

The A216 WCB ball valve comes in several types, each tailored for specific applications. Full port, reduced port, and V-port are among the common designs, catering to different flow rate requirements. These valves are integral in sectors ranging from water treatment to petrochemical industries, due to their ability to provide secure and efficient flow control.

Features and Materials

A carbon steel ball valve is characterized by its material strength, making it suitable for high-pressure environments. The A216 WCB grade ensures durability against thermal stress, while the ball mechanism provides precise control with minimal wear. Additional features like blow-out proof stems and ISO mounting pads enhance the valve's functionality and safety.

Advantages of A216 WCB Ball Valves

The advantages of using an A216 WCB valve are manifold. Its tight shut-off capabilities make it an excellent choice for liquid and gas applications, while the low torque operation allows for easy automation. The longevity and low maintenance requirements of a cast steel ball valve ensure it is a cost-effective option for industrial use.

Selection Considerations

When selecting a WCB ball valve, it's essential to consider factors such as the size, pressure class, and end connection type. These valves are available in a range of sizes and classes to match the specific needs of a piping system, ensuring optimal performance and compatibility.

Environmental and Operational Efficiency

Environmental sustainability and operational efficiency are key in modern industries, and the flanged ball valve aligns with these priorities. Its design minimizes the risk of leakage, promoting safer and more environmentally friendly operations across various applications.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4