Exploring the Versatility of Abrasive Discs

Abrasive discs are essential components in various industrial, construction, and manufacturing processes. These discs are designed to cut, grind, and finish surfaces, making them indispensable in the preparation and finishing of materials.

Types and Applications

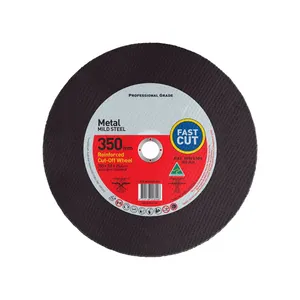

There are several types of abrasive discs, each suited for specific tasks. The cutting disc is tailored for slicing through materials with precision, while the grinding disc is used to smooth out imperfections. For finishing tasks, the sanding disc provides the necessary abrasion to achieve a fine finish. These discs are utilized in fields ranging from metal fabrication to woodworking and automotive repair.

Material Composition and Features

The materials used in abrasive discs include aluminum oxide, silicon carbide, zirconia alumina, and ceramic. Each material offers distinct features; for instance, silicon carbide discs are known for their sharpness and hardness, which are ideal for working on materials like stone and glass. The structure of these discs is also designed for durability, with features such as reinforced fiberglass meshing that provides additional strength.

Advantages of Using Abrasive Discs

The use of abrasive discs brings several advantages to the workplace. Their ability to remove material quickly and efficiently can significantly reduce the time spent on surface preparation. Moreover, the variety of available grit sizes allows for a range of finishes, from rough to ultra-smooth. The versatility of these discs means they can be adapted to both hand-held tools and large-scale machinery, catering to different project scales.

Selection Considerations

When selecting an abrasive disc, it is crucial to consider the material to be worked on and the desired finish. The disc's compatibility with the tool in use is also an important factor, as is the disc's speed rating, which must match the tool's RPM to ensure safe operation. Environmental factors, such as the generation of dust and debris, should also be taken into account, as they can affect both the efficiency of the disc and the health and safety of the operator.

Discovering the Right Abrasive Disc on Alibaba.com

For professionals seeking a reliable source of abrasive tools, Alibaba.com offers a diverse selection of abrasive discs. Whether the task at hand involves a flap disc, a fiber disc, or a polishing disc, the platform connects buyers with a multitude of suppliers to meet their specific needs. With a focus on variety and accessibility, Alibaba.com serves as a valuable resource for sourcing these critical components for any project.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4