A Comprehensive Guide to Abrasive Gauze

The realm of surface finishing and material preparation is incomplete without mentioning abrasive gauze. This versatile tool is essential for professionals seeking to achieve a flawless finish on various surfaces. Abrasive gauze is a flexible, fabric-like material embedded with abrasive particles, designed to conform to different shapes and contours during the sanding process.

Types and Applications of Abrasive Gauze

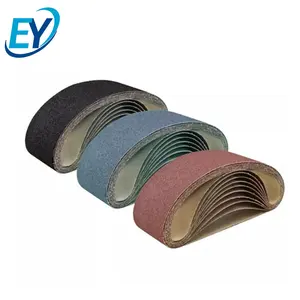

Abrasive gauze comes in various forms, each tailored for specific applications. The common types include hand pads, rolls, and sheets. These are utilized in a multitude of settings, from woodworking and metal fabrication to automotive refinishing and DIY projects. The flexibility of abrasive gauze makes it particularly useful for smoothing irregular surfaces and reaching into tight corners where traditional sanding tools may not be effective.

Features and Materials

The construction of abrasive gauze involves a mesh backing made from materials such as cotton, polyester, or a blend, which provides both strength and flexibility. The abrasive particles, typically aluminum oxide or silicon carbide, are bonded to the mesh. This unique composition allows for uniform abrasion and minimizes clogging, enhancing the longevity of the gauze.

Advantages of Using Abrasive Gauze

One of the primary advantages of using abrasive gauze is its durability. Unlike paper-based abrasives, the gauze does not tear easily, making it suitable for heavy-duty tasks. Additionally, its open mesh structure promotes airflow, reducing heat buildup and preventing damage to the workpiece. The inherent flexibility allows users to apply uniform pressure, resulting in a consistent finish.

Selecting the Right Abrasive Gauze

Choosing the correct abrasive gauze for a project is crucial. Factors such as grit size, type of abrasive material, and the backing's strength should be considered. For fine finishing, a higher grit number with a gentler abrasive material like aluminum oxide is recommended. Conversely, for more aggressive material removal, a lower grit with a robust material like silicon carbide is preferable.

Alibaba.com offers a diverse selection of abrasive gauze to cater to various industry needs. Whether the task at hand involves delicate surface preparation or rigorous material removal, the platform connects buyers with a wide array of options. Explore the range of abrasive gauze products to find the perfect match for your project requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4