A Comprehensive Guide to Abrasive Polishing Wax

Abrasive polishing wax plays a pivotal role in various industries, serving as a critical component in the finishing process of numerous products. This guide delves into the intricacies of abrasive polishing wax, its types, applications, and features, providing a thorough understanding of its significance in industrial, domestic, and technological applications.

Understanding Abrasive Polishing Wax

Abrasive polishing wax is a specialized substance used to smooth surfaces and enhance the finish of a material. It is a blend of abrasive materials and wax, which acts as a binder. The abrasive components can range from natural minerals like garnet and diamond to synthetic elements such as boron carbide and ceramic particles. The choice of abrasive in the wax depends on the desired outcome, from aggressive material removal to fine polishing.

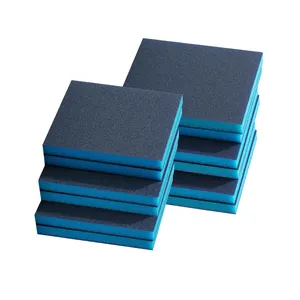

Types and Forms

The versatility of abrasive polishing wax is evident in its various forms. Bonded abrasives, typically found in wheels, sticks, or blocks, are designed for rigorous tasks like grinding and cutting. Coated abrasives, suitable for wrapping around tools, cater to sanding and honing operations. Each form is crafted to meet specific surface treatment requirements, ensuring that there is a suitable option for every task.

Applications Across Industries

The application of abrasive polishing wax extends across multiple sectors. In the industrial realm, it is essential for preparing metal surfaces, while in the domestic sphere, it contributes to the maintenance of household items. Technological advancements have further expanded its use to include the precise polishing of electronic components, where precision and surface integrity are paramount.

Features and Advantages

The efficacy of abrasive polishing wax is attributed to its features, such as grain size and adhesion properties. These characteristics determine the level of abrasiveness and the finish quality on different materials. Users can select from a range of grain sizes, from coarse grains for substantial material removal to fine grains for a polished finish. The adhesion quality of the wax ensures that the abrasive particles remain intact during the application, providing consistent results.

One of the primary advantages of using abrasive polishing wax is its ability to produce a high-quality finish while minimizing material waste. The wax's composition allows for a controlled abrasion process, leading to a smoother finish with fewer passes, thus saving time and resources.

Selecting the Right Abrasive Polishing Wax

Choosing the correct abrasive polishing wax requires consideration of the material to be polished, the desired finish, and the application method. Alibaba.com offers a diverse selection of abrasive polishing waxes to cater to these varied needs. By understanding the specific requirements of their task, buyers can make informed decisions and source the appropriate wax to achieve optimal results.

For those looking to procure abrasive polishing wax, Alibaba.com serves as a comprehensive marketplace, connecting buyers with a multitude of suppliers offering products tailored to a wide array of applications. Without endorsing any particular brand or making quality claims, the platform facilitates the discovery of products that align with buyers' unique requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4