Popular in your industry

Related Searches:

Top categories

About abs bumper mold

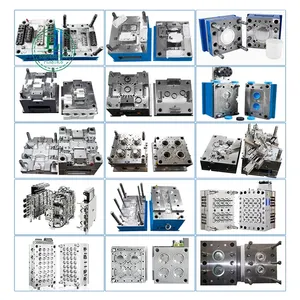

Introduction to ABS Bumper Molds

ABS bumper molds are specialized tools used in the manufacturing of durable and impact-resistant bumpers for various vehicles. These molds are designed to shape acrylonitrile butadiene styrene (ABS), a common thermoplastic polymer, into precise bumper forms through the injection molding process. The adaptability of ABS material allows for the creation of bumper designs that meet specific aesthetic and functional requirements.

Types and Applications

The versatility of ABS bumper molds caters to a wide range of applications. From compact cars to large commercial vehicles, the molds are engineered to produce bumpers that are integral to vehicle safety and design. In addition to automotive use, these molds are also utilized in the production of bumpers for off-road vehicles and other specialized transportation equipment, where durability and resilience are paramount.

Features and Materials

Injection molding technology is at the core of ABS bumper mold manufacturing. This process ensures precision and repeatability, which are crucial for the mass production of vehicle bumpers. The molds themselves are typically constructed from robust materials such as steel or aluminum, offering longevity and the ability to withstand the high pressures of injection molding. The choice of material for the mold impacts its performance and the quality of the final product.

Advantages of ABS Bumper Molds

Utilizing ABS bumper molds in production brings several advantages. The inherent strength of ABS allows for the creation of bumpers that are lightweight yet sturdy, providing essential protection without significantly adding to the vehicle's weight. Moreover, the efficiency of the injection molding process reduces waste and can enhance production speed, making it a cost-effective solution for bumper manufacturing.

Customization and Standardization

Customization is a key feature of ABS bumper mold services, allowing for the creation of unique bumper shapes and sizes. Manufacturers can tailor molds to specific design requirements, ensuring that the end product aligns with brand aesthetics and functional specifications. Additionally, standardization options are available for businesses looking to streamline their production process. Features such as uniform lift bars, connection sizes, and clamp slots can be standardized across molds to simplify the manufacturing workflow.

Selecting the Right Mold

Choosing the appropriate ABS bumper mold is a critical decision that influences the quality and efficiency of production. Alibaba.com hosts a diverse array of mold options, facilitating the connection between businesses and expert mold manufacturers. By leveraging the platform, buyers can communicate their needs, explore customization options, and select molds that align with their production goals, all while ensuring compatibility with their existing systems.