Exploring Aluminum Can Recycling Devices

Aluminum can recycling devices are sophisticated tools engineered to streamline the recycling process for aluminum beverage containers. These devices are crucial for a broad spectrum of participants in the beverage sector, from modest enterprises to expansive recycling facilities. They play a pivotal role in diminishing waste, conserving resources, and curtailing the ecological footprint of aluminum usage and production.

The aluminum can recycling sequence entails the accumulation, categorization, and refinement of cans to guarantee their suitability for reincorporation into new products. This cycle commences with consumers and businesses disposing of spent cans, which are then gathered by recycling depots or salvage yards, often offering monetary rewards for their submission. Subsequently, the cans are subjected to a series of procedures, such as compression, disintegration, and liquefaction, to extract the aluminum from any impurities like paper or plastic. The reclaimed metal is then ready to be fashioned into fresh cans or other aluminum items.

Aluminum can recycling devices are conceived with efficiency, dependability, and ecological advantages in mind, making them indispensable in the shift towards a sustainable, circular economy. By capitalizing on aluminum's substantial scrap value and repurposing it, these devices contribute to completing the supply chain loop and diminish the demand for virgin materials.

Varieties of Aluminum Can Recycling Devices

Aluminum can recycling devices are available in diverse configurations, each tailored to meet specific needs, offering a flexible option for businesses intent on adopting eco-friendly practices. Common variants include:

-

Can Crushers: These devices compress and diminish the size of aluminum cans for more straightforward handling and transportation, ideal for domestic use or in commercial locales like eateries with high can turnover.

-

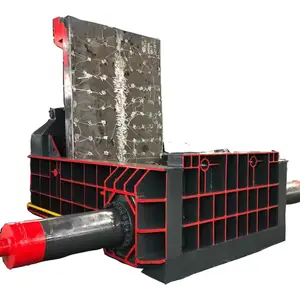

Can Densifiers: Suited for operations handling copious amounts of cans, these machines compact numerous cans into tight bales or blocks, saving space and simplifying material management.

-

Aluminum Melting Furnaces: These furnaces are indispensable in industrial settings for rapid melting of substantial aluminum quantities, utilizing various heating techniques such as direct flame or electrical resistance.

-

Portable Aluminum Can Recycling Devices: These compact units are perfect for individual or small-scale business use, attachable to walls or stands, and capable of collecting a considerable number of cans before requiring emptying.

Each device type is suited to particular applications, whether it's minimizing waste volume in a domestic kitchen or enhancing recycling efficiency in a bustling eatery.

Selecting an Aluminum Can Recycling Device

In choosing an aluminum can recycling device for your enterprise, consider the expected volume of cans and the space available for the equipment. The device should match your operational demands and spatial limitations.

For entities with fewer cans, manual crushers may be adequate. These economical tools are apt for processing a modest number of cans. Conversely, for larger volumes, an automatic crusher, capable of managing increased capacity and streamlining the recycling process, may be more fitting.

Automation level is another consideration. Automated devices can curtail labor expenses but might require a heftier upfront investment. Nonetheless, their enhanced efficiency can lead to long-term cost savings.

Also, contemplate the state of the cans to be recycled. If dealing with highly compressed cans, specialized machinery capable of processing such materials without further damage may be necessary.

Lastly, factor in after-sales service and maintenance support when selecting a recycling device. Dependable technical assistance can reduce downtime due to maintenance or operational queries.

Aluminum Can Recycling Devices on Alibaba.com

Alibaba.com distinguishes itself as a global marketplace that connects purchasers with suppliers, offering a wide array of products for diverse commercial needs. For those seeking dependable aluminum can recycling devices, Alibaba.com offers an effective platform for businesses aiming to integrate sustainable methods while upholding high operational standards.

The platform's extensive selection enables buyers to peruse a variety of aluminum can recycling devices suitable for different operational scales—from quaint coffee shops to major food processing enterprises. With robust construction materials like stainless steel and sophisticated filtering options, businesses can locate devices that promise durability and precise material sorting.

Furthermore, Alibaba.com eases international commerce by providing services such as Trade Assurance, which safeguards payments until delivery confirmation, thus enhancing trust between buyers and suppliers. The site's dedication to streamlining business transactions globally positions it as an exemplary source for procuring commercial-grade equipment that aligns with your firm's specific requirements without compromising quality or efficiency.

Frequently Asked Questions About Aluminum Can Recycling Devices

What varieties of aluminum can be processed with these devices?

These devices are adept at recycling a wide range of aluminum cans and containers, among other aluminum items. It's crucial to verify each machine's specific capabilities to ensure it satisfies your recycling demands.

How does an aluminum can recycling device operate?

An aluminum can recycling device functions by compressing, shredding, or crushing cans to a more manageable size, with the process being either automated or semi-automated based on the design of the machine.

Are these devices capable of managing substantial volumes of aluminum waste?

Indeed, there are industrial-grade machines engineered to process significant volumes of aluminum waste, typically more robust and capable of sustained operation in high-output environments.

Do these devices suit small-scale businesses?

Certainly, there are devices expressly designed for small businesses that efficiently manage lesser quantities of aluminum. Selecting a machine that corresponds with your business's recycling volume is essential.

What considerations are important when selecting an aluminum can recycling device for my business?

Key factors to consider include the machine's capacity, operational simplicity, maintenance needs, energy usage, and the types of aluminum waste you intend to process.

How can I ascertain the appropriate machine size for my business?

Evaluate the amount of material you plan to recycle and the scale of your operation. Larger machines generally offer greater capacities and can process more material simultaneously, which is advantageous for operations with high volumes.

What kind of after-sales support is available for these devices?

After-sales support varies among suppliers but may encompass video technical assistance, online support, engineers for overseas machinery servicing, or on-site maintenance and repair services.

Is it possible to find a machine that processes multiple types of recyclable materials?

Yes, multifunctional machines are available that can manage a variety of recyclable materials, including aluminum cans, plastic bottles, scrap metal, and more.

Are there energy-efficient models among these devices?

Certain models are designed with energy-conserving features that can help lower operational costs over time. Seek devices with energy-saving modes if energy efficiency is a priority for your enterprise.

How can I ensure the durability of my aluminum can recycling device?

Adhere to the manufacturer's guidelines for operation and maintenance, utilize the machine within its capacity limits, and promptly replace any worn components to maintain its longevity.

Is a dedicated power supply necessary for these devices?

These machines typically require a standard electrical outlet. Ensure the voltage and frequency specifications are compatible with your local power supply when choosing a model.

What safety measures should be observed when operating an aluminum can recycling device?

Always employ appropriate personal protective gear such as gloves and safety goggles. Heed all operational instructions and employ safety guards as needed to avert mishaps.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4