Introduction to Aluminum Shoe Sole Molds

Aluminum shoe sole molds are essential components in the footwear manufacturing industry, serving as the foundational tools for crafting the soles of shoes. These molds are designed to shape and solidify materials into a precise sole structure, which is critical for both the functionality and aesthetics of the shoe. The use of aluminum in these molds is favored due to its excellent thermal conductivity, lightweight nature, and durability, making it an ideal choice for consistent and efficient production.

Types and Applications

There are various types of aluminum shoe sole molds tailored to different shoe-making processes and styles. From athletic sneakers to formal footwear, each mold is engineered to meet the specific requirements of the shoe design. These molds are not only used for injection molding but also for compression and transfer molding processes, accommodating a wide range of production needs. The application of these molds spans across the footwear industry, highlighting their versatility in producing soles for diverse market segments.

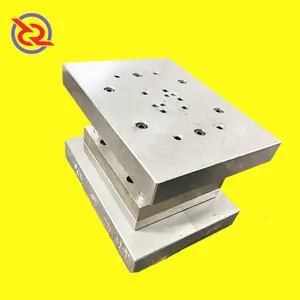

Features and Materials

The construction of an aluminum shoe sole mold is a precise science, focusing on features that enhance the mold's performance and longevity. Aluminum's inherent properties contribute to the mold's heat distribution capabilities, which is crucial for curing materials quickly and evenly. Additionally, the surface treatment of the mold can be customized to various textures and finishes, depending on the sole design requirements. While aluminum is the primary material, other supportive components may be incorporated to enhance the mold's functionality.

Advantages of Aluminum Molds

Opting for an aluminum shoe sole mold comes with a host of advantages. The material's lightness facilitates easier handling and quicker cooling times, leading to increased production efficiency. Aluminum also exhibits resistance to corrosion, which extends the mold's lifespan and ensures consistent quality in sole production. Furthermore, the adaptability of aluminum allows for the creation of complex sole designs, which can cater to the ever-evolving trends in the footwear industry.

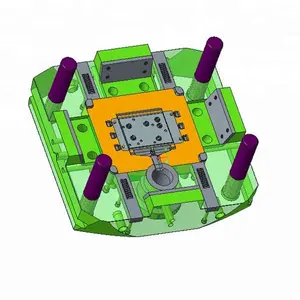

Standardization and Efficiency

Efficiency in production is a key consideration when selecting a shoe sole mold. Manufacturers can enhance their operational efficiency by standardizing certain elements of the mold, such as lift bars, connection sizes, and clamp slots. This standardization enables seamless integration with existing production lines and simplifies the manufacturing process, especially when dealing with multiple shoe models and designs.

Choosing the Right Mold

Selecting the appropriate aluminum shoe sole mold is a critical decision that impacts the quality and cost-effectiveness of shoe production. It is important to consider the specific requirements of the shoe design, the compatibility with production machinery, and the potential for customization. Suppliers on Alibaba.com offer a range of options and can provide insights to assist buyers in making informed decisions, ensuring that the chosen mold aligns with their production goals and quality standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4