Popular in your industry

Top categories

About auto cone winding machines

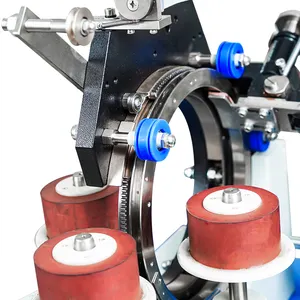

Introduction to Auto Cone Winding Machines

Auto cone winding machines are integral to the textile and electrical appliance manufacturing industries, streamlining the process of winding fibers and wires into coils. These machines are designed to enhance productivity by automating the coil winding process, which is essential in creating components like solenoids and transformers. The versatility of these machines allows them to be utilized in various settings, from large-scale industrial operations to smaller, cottage industry environments.

Types and Applications

The range of auto cone winding machines includes autonomous, semi-automatic, and manual models, each serving distinct production needs. Autonomous and automatic cone winder models are favored in high-volume environments where efficiency and precision are paramount. Semi-automatic variants offer a balance of control and automation, suitable for diverse manufacturing requirements. Manual winding machines remain relevant for specialized tasks where a hands-on approach is preferred.

Operational Features

Auto cone winding machines are engineered with features that promote ease of use and consistent performance. Many models are equipped with advanced control panels that allow operators to set parameters that meet specific production needs. The precision of these machines ensures uniformity in coil winding, which is critical for the functionality of electrical components. Additionally, the design often allows for a single operator to manage the winding process, optimizing labor resources.

Material and Construction

Constructed to meet international production standards, auto cone winding machines are built with durability in mind. The materials used in their construction are selected for longevity and the ability to withstand the rigors of continuous operation. This focus on quality materials ensures that the machines require minimal maintenance, allowing for uninterrupted production cycles.

Advantages of Utilizing Auto Cone Winding Machines

Incorporating an automatic cone winder into a production line can significantly reduce the time spent on coil winding tasks. This efficiency gain not only boosts output but also allows for the reallocation of labor to other productive activities. The precision offered by these machines minimizes waste and ensures that the end product meets the required specifications. Furthermore, the consistency in the coils produced aids in maintaining the quality of the final electrical appliances.

Selection and Support

Alibaba.com hosts a diverse array of auto cone winding machines, ensuring that businesses can find a model that aligns with their operational needs. While the platform facilitates the connection between buyers and suppliers, it also ensures that the products listed adhere to qualitative benchmarks. Support in the form of product guidelines is often available, and suppliers may provide demonstrations to ensure that buyers can leverage the full potential of their purchase.