Popular in your industry

Top categories

About automat cnc

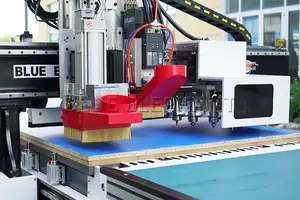

Introduction to Automat CNC Machinery

Automat CNC machinery is a revolutionary technology in the manufacturing industry, combining automation with computer numerical control (CNC) systems to enhance precision, efficiency, and productivity in machining processes. These machines are equipped with advanced features and capabilities to streamline production, reduce human intervention, and ensure consistent output quality.

The Evolution of CNC Tool Changer

One of the key advancements in automat CNC machinery is the integration of a 'cnc tool changer'. This feature allows for automatic changing of cutting tools during the machining process, eliminating downtime and increasing operational efficiency. CNC tool changers come in various configurations, such as umbrella, arm-type, and rotary, catering to different production needs.

Enhancing Productivity with CNC Automat

The implementation of 'cnc automat' in manufacturing processes has significantly boosted productivity levels. These systems can operate continuously, performing complex machining tasks with minimal human supervision. By automating repetitive tasks and optimizing tool changes, CNC automat machinery ensures faster production cycles and higher output rates.

Optimizing Operations with CNC and Tool Changer Integration

Combining 'cnc with tool changer' capabilities offers manufacturers a comprehensive solution for optimizing their operations. The seamless integration of CNC controls with automatic tool changers allows for precise machining operations while minimizing setup time. This integration results in improved accuracy, reduced lead times, and enhanced overall production efficiency.

Advanced CNC Machinery: The YCQ4-100E Model

The 'cnc YCQ4-100E' model represents the pinnacle of CNC machinery technology, featuring state-of-the-art components and intelligent systems. With high-speed machining capabilities, multi-axis control, and a sophisticated tool changer mechanism, the YCQ4-100E is designed to meet the demands of modern manufacturing environments.

Key Features of Automat CNC Machinery

Automat CNC machinery is equipped with a range of advanced features that set it apart in the industry. These include high-precision ball screws, rigid machine structures, advanced spindle technologies, and user-friendly CNC controls. Additionally, the integration of automatic tool changers and robotic systems further enhances the operational efficiency and versatility of these machines.

Benefits of CNC Automation in Manufacturing

The adoption of CNC automation in manufacturing processes offers numerous benefits to businesses. Increased productivity, reduced labor costs, improved product quality, and faster time-to-market are some of the key advantages. By leveraging automat CNC machinery, manufacturers can stay competitive in a rapidly evolving market landscape.

Choosing the Right CNC Machinery for Your Business

When selecting automat CNC machinery for your business, it's essential to consider factors such as production volume, machining complexity, required precision, and available floor space. Assessing your specific needs and production goals will help you choose the right machine model with the optimal tool changer configuration to maximize operational efficiency.

Maintenance and Care for CNC Automat Systems

Proper maintenance of automat CNC systems is crucial to ensure long-term performance and reliability. Regular inspection of components, lubrication of moving parts, calibration of sensors, and software updates are some of the key maintenance tasks. By following manufacturer guidelines and scheduling routine maintenance checks, businesses can prolong the lifespan and efficiency of their CNC automat machinery.

Conclusion

In conclusion, automat CNC machinery represents the future of manufacturing, offering businesses a competitive edge through automation, precision, and efficiency. By embracing CNC technology with advanced tool changer capabilities, manufacturers can optimize their operations, increase productivity, and deliver high-quality products to meet market demands.