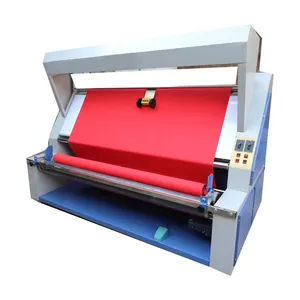

Introduction to Automatic Fabric Winder Machines

The realm of textile production has been revolutionized by the advent of the automatic fabric winder machine. This equipment is essential for businesses that focus on fabric handling and processing, streamlining the task of winding fabric into rolls post-production. The automatic fabric winder serves as a critical component in the textile industry, ensuring efficiency and consistency in fabric roll quality.

Types and Applications

There are various types of fabric winders, including autonomous, semi-automatic, and manual models, each serving distinct production needs. The application of these machines spans across different sectors, from small-scale home operations to large industrial factories specializing in electrical appliances. The industrial fabric winder is particularly beneficial for mass production, where it aids in the swift coiling of transformer and solenoid wires.

Features and Materials

An automatic cloth winder is designed with features that promote ease of use and precision. These machines are constructed from durable materials that withstand the demands of continuous operation. With user-friendly interfaces, they allow operators to manage the winding process with minimal manual intervention. The adaptability of these machines means they can handle a variety of fabric types, from delicate textiles to more robust materials.

Advantages of Automation in Winding

The transition to an automated winding machine from manual methods offers numerous advantages. Efficiency is significantly enhanced, as these machines can operate continuously without the need for constant supervision. This automation reduces the labor required, allowing a single individual to oversee the operation. Furthermore, the precision of an automatic winder ensures consistent quality in coil formation, which is crucial for maintaining production standards.

Maintenance and Operation

Ease of maintenance is another key feature of the textile winder machine. Designed to require minimal upkeep, these machines can operate for extended periods without the need for frequent servicing. They come equipped with clear instructions and guidelines, ensuring that operators can maintain them properly to avoid downtime.

Choosing the Right Machine

Selecting the appropriate fabric winding equipment is vital for meeting specific production requirements. Suppliers on Alibaba.com offer a wide range of machines, each designed to cater to different scales of operation and fabric types. While browsing the extensive inventory, buyers can find machines that align with their operational needs and production capacities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4