Popular in your industry

Related Searches:

Top categories

About automatic machine cnc

Introduction to Automatic Machine CNC

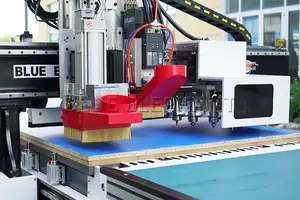

Automatic machine CNC, also known as computer numerical control, is a cutting-edge technology that automates machine tools through pre-programmed sequences. This technology revolutionizes industrial manufacturing by enhancing precision, efficiency, and productivity. The integration of automation and CNC capabilities allows for complex and intricate machining processes to be executed with utmost accuracy.

Design Innovation in CNC Automatic Machines

The design of CNC automatic machines incorporates advanced features to optimize performance and functionality. These machines are equipped with high-precision servo motors, ball screws, and linear guides to ensure smooth and precise movement during machining operations. Additionally, modern CNC automatic machines are built with rigid structures and vibration damping mechanisms to enhance stability and reduce machining errors.

Technical Specifications of CNC Ceiling Fan Winding Machine

One of the specialized types of CNC automatic machines is the CNC ceiling fan winding machine. This machine is specifically designed for the automated winding of coils in ceiling fan stator assemblies. The CNC ceiling fan winding machine features multiple axes control, high-speed winding capabilities, and programmable winding patterns. With a user-friendly interface and precise tension control, this machine ensures consistent winding quality for ceiling fan production.

Advantages of Automated CNC Machines

Automated CNC machines offer a multitude of advantages for industrial applications. These machines significantly reduce manual intervention, leading to improved production efficiency and consistency. The automation provided by CNC technology minimizes human errors, resulting in higher accuracy and repeatability in machining processes. Moreover, automated CNC machines enable manufacturers to optimize production schedules and meet stringent quality standards.

Choosing the Right Automatic CNC Machine

When selecting an automatic CNC machine for your business needs, several factors should be considered to ensure optimal performance and return on investment. Firstly, assess the specific machining requirements of your production processes to determine the necessary machine specifications such as spindle speed, tool capacity, and axis configurations. Additionally, consider the software compatibility and ease of programming to streamline operations and maximize productivity.

Maintenance Tips for CNC Automatic Machines

Proper maintenance is essential to prolong the lifespan and performance of CNC automatic machines. Regularly inspecting and cleaning machine components such as spindle assemblies, ball screws, and lubrication systems can prevent premature wear and malfunction. It is crucial to follow manufacturer guidelines for lubrication schedules and replace worn-out parts promptly to avoid costly breakdowns. Implementing a preventive maintenance routine can optimize the efficiency and reliability of CNC automatic machines.