Introduction to Ball Pen Making Equipment

The manufacturing of ballpoint pens is a precise process that requires specialized ball pen making equipment. This category encompasses a variety of machines and tools designed to produce high-quality writing instruments. From the initial stages of barrel formation to the final assembly of ink refills, each piece of equipment plays a crucial role in the pen production line.

Components and Machinery

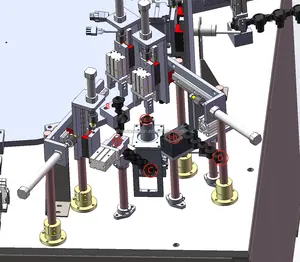

In the realm of pen manufacturing, precision is paramount. The ball pen assembly machine is at the heart of production, ensuring each pen is constructed accurately. Complementary to this, the refill assembly machine is tasked with the intricate process of fitting the ink refill within the pen's barrel. For the outer casing, the barrel making machine shapes and molds the pen's body, which is then printed with logos and designs using the pen printing machine. Each component is integral to the seamless operation of the production line.

Material and Design Considerations

The choice of materials in pen manufacturing affects the performance and durability of the final product. Equipment such as the ink filling machine must handle various ink viscosities and compositions. Similarly, the tip fitting machine precisely inserts the ballpoint tip, made from a hard metal like tungsten carbide, ensuring smooth writing. The design process also involves pen testing equipment to check for ink flow consistency and writing longevity.

Operational Features

Efficiency and reliability are key features of ball pen making equipment. Machines are designed for continuous operation, minimizing downtime and maximizing output. The automation within the pen packing machine streamlines the packaging process, preparing the pens for distribution. Additionally, the adaptability of the automatic pen making machine allows for the production of various pen models and designs, catering to diverse market demands.

Environmental Impact and Sustainability

Modern pen manufacturing also considers environmental impact. Equipment like the eco-friendly pen making machine is engineered to reduce waste and energy consumption. Manufacturers are increasingly seeking machines that support the use of biodegradable materials, reflecting the industry's shift towards sustainability.

Choosing the Right Supplier

Selecting the appropriate supplier for ball pen making equipment on Alibaba.com involves evaluating the technical specifications, production capacity, and reliability of the machinery. While exploring the vast array of options, buyers should focus on the equipment's compatibility with their production goals and the supplier's reputation for quality and service.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4