Popular in your industry

Related Searches:

Top categories

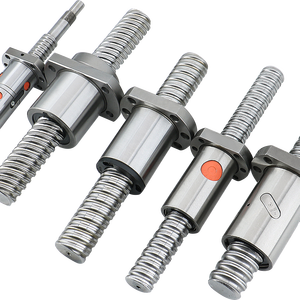

About ball screw injection machine

Introduction to Ball Screw Injection Machines

Ball screw injection machines represent a significant advancement in the field of plastic molding technology. These machines are integral to the manufacturing process, transforming plastic granules into a myriad of precise shapes and sizes. The core mechanism, the ball screw, enhances the precision and efficiency of the injection process, making these machines a staple in various industries.

Design and Functionality

The design of a ball screw injection machine is a testament to engineering precision, aimed at ensuring consistent performance and longevity. The incorporation of a single-cylinder system with a servo-valve ensures a swift response rate during operation, which is crucial for maintaining productivity. The specialized screw design is pivotal in increasing the plasticizing shot weight and speed, which are essential factors in the injection molding process.

Applications and Versatility

Versatility is a hallmark of the ball screw injection molding machine, with its ability to cater to a diverse range of applications. From creating intricate components for consumer electronics to producing essential parts for the pharmaceutical, food and beverage, and automotive sectors, these machines are designed to meet the rigorous demands of various industries. The adaptability of these machines to manufacture products like thin-wall containers, caps, and PVC pipe fittings underscores their importance in the packaging industry.

Features and Materials

A ball screw injection molder is engineered with features that emphasize durability and service life. The steel bush in the clamping unit is constructed to minimize wear resistance, which in turn reduces the need for frequent lubrication, leading to cost savings in maintenance. With a clamping force that ranges significantly, these machines are capable of resisting the substantial external forces encountered during the molding process.

Advantages of Using Ball Screw Injection Molding

Investing in a ball screw injection molding machine offers several advantages. The precision of the ball screw mechanism ensures improved accuracy in the final product dimensions, which is critical for high-end applications. Additionally, the robust construction of these machines provides the exact clamping force needed for specific tasks, ensuring efficient use of resources and energy.

Choosing the Right Machine

Selecting the appropriate ball screw injection machine is crucial for any plastic processing business. Alibaba's platform connects buyers with a wide array of machines, each designed to shape plastic granules into desired dimensions with improved accuracy. When browsing the selection, consider the specific requirements of your applications to find a machine that aligns with your production needs.