Introduction to Batch Furnaces

A batch furnace is a pivotal component in the industrial sector, designed for the thermal processing of materials. This category encompasses a variety of systems tailored for heating batches of materials, often metals, to alter their physical and chemical properties for further use in manufacturing.

Types and Applications

The batch type furnace is versatile, catering to different industrial needs. Applications range from melting scrap metals to crafting various steel types from iron. Specific models are optimized for metals like iron, aluminum, and copper, while others cater to precious metals such as gold, silver, and platinum. The adaptability of these furnaces makes them indispensable in fields such as metalworking, automotive, and aerospace industries.

Features and Design

Each batch furnace boasts a robust design, with some capable of handling up to 20 tons of material. They operate on power inputs from 380v to 950v and offer working power from 180kw to 2,000kw. Advanced models include large capacitor banks to stabilize the current, ensuring efficient energy use and consistent performance. Safety is paramount, with integrated systems like circuit breakers to mitigate faults during operation.

Operational Advantages

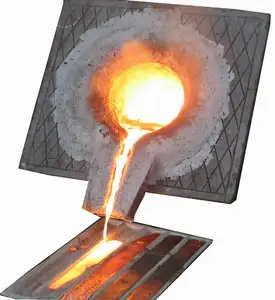

The operational efficiency of a batch annealing furnace is evident in its melting capabilities, providing temperatures from 2,100 to 1,750 degrees Celsius. This range is sufficient to process most metals within 40 to 60 minutes. Additionally, the melting pots in these furnaces can tilt up to 95 degrees, facilitating the easy transfer of molten metal.

Cooling and Control Systems

To manage the high temperatures, each batch type furnace is equipped with a water-cooling system. This not only extends the life of the furnace but also ensures the safety of the operation. Control is streamlined through a PLC system, which allows for precise adjustments and monitoring of the melting process.

Technological Integration

Modern batch furnaces leverage electrical induction systems for heating, providing a clean and efficient melting process. The inclusion of hydraulic pressure systems offers the necessary tilting force, enhancing the functionality and ease of operation. Such technological advancements underscore the continuous evolution of batch furnaces to meet industrial demands.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4