Popular in your industry

Related Searches:

Top categories

About bearing 35x62x17

Introduction to Precision Bearings

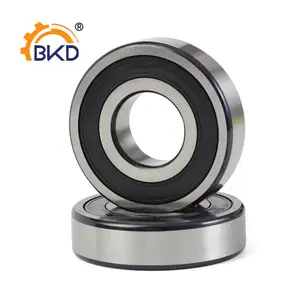

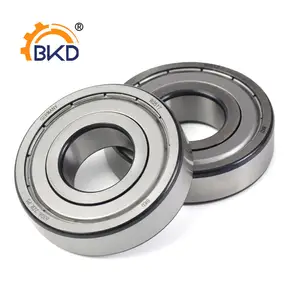

Bearings are pivotal components in the mechanical world, facilitating smooth motion and reducing friction between moving parts. Among the various types, the bearing 35x62x17 stands out for its specific dimensions, catering to precise industrial needs. This category of bearings is designed to fit a niche of applications where a diameter of 35mm, an outer diameter of 62mm, and a width of 17mm are required.

Types and Materials

The bearing 35x62x17 comes in several types, including deep groove ball bearings, angular contact bearings, and tapered roller bearings, each serving distinct purposes. Materials range from chrome steel to advanced ceramics, with the former providing durability and the latter offering reduced weight and increased longevity.

Applications and Features

With its precise dimensions, the bearing 35x62x17 is utilized in a variety of applications. It's found in automotive components, industrial machinery, and even in high-precision devices like medical equipment. The features of this bearing include high rotational accuracy and the ability to handle both radial and axial loads effectively.

Advantages of Precision Bearings

The advantages of using a bearing 35x62x17 are numerous. Its compact size allows for use in tight spaces without sacrificing performance. The precision manufacturing ensures longevity and reliability in operation, which is crucial for industries that cannot afford downtime.

Selection Considerations

When selecting a bearing 35x62x17, it's important to consider the application's load requirements, speed, and environmental conditions. This ensures that the bearing will operate efficiently and have a suitable service life in its intended application.

Maintenance and Care

Proper maintenance is key to extending the life of any bearing. For the bearing 35x62x17, regular lubrication, cleaning, and inspection for wear and tear are recommended to maintain optimal performance.