Understanding the Blade Spindle

A blade spindle is a critical component in various machinery, playing a pivotal role in the performance of equipment such as mowers, lathes, and milling machines. This cylindrical part is designed to hold and rotate the cutting tool or blade, enabling precise and efficient operations across different applications.

Types and Applications

The versatility of blade spindles is evident in their wide range of types, each tailored to specific machinery. For instance, a mower blade spindle is integral to the performance of lawn mowers, ensuring a clean and even cut. In contrast, a spindle blade for industrial machines must withstand higher demands, adapting to the rigors of materials like metal or wood.

Specialized variants such as the John Deere l120 spindles or the craftsman 42 in deck spindle are engineered to fit specific models, ensuring compatibility and performance. Similarly, the gravely ztx 52 spindle is designed for the Gravely line of mowers, highlighting the importance of matching the spindle to the machine's make and model.

Features and Materials

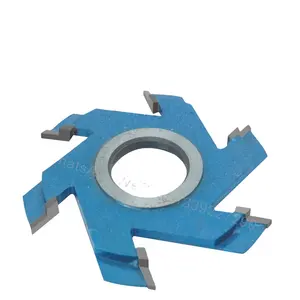

The construction of a blade spindle involves durable materials capable of enduring the stress of rotation and cutting. Materials like alloy steel or aluminum are commonly used for their strength and resistance to wear. For example, the husqvarna blade spindle is known for its robust build, ensuring longevity and reliability.

Moreover, features such as sealed bearings and precise geometry are crucial for the spindle's functionality. These characteristics prevent debris ingress and maintain alignment, which is essential for the ariens ikon x 52 spindle used in precision mowing equipment.

Advantages of Quality Spindles

Investing in a quality blade spindle can lead to significant advantages, such as improved machine performance and reduced maintenance costs. A well-crafted john deere d140 deck spindle or a blade spindle for craftsman riding mower ensures that the machine operates at peak efficiency, providing a consistent output.

Furthermore, the right lawn mower blade spindle can minimize vibration, leading to a smoother operation and less wear on other components. This is particularly important for professional landscaping equipment, where uptime and precision are paramount.

Choosing the Right Blade Spindle

Selecting the appropriate blade spindle requires consideration of the machine's specifications and the intended use. For residential lawn care, a poulan pro 42 inch deck spindle might be sufficient, while commercial operations might necessitate a more robust option like the 618p09395 model.

Compatibility is key, as seen with the john deere l130 spindles and 918 04512b models, which are designed to fit specific John Deere mowers. Ensuring that the spindle matches the machine's requirements can prevent operational issues and extend the equipment's service life.

Conclusion

The blade spindle is a fundamental component for many types of machinery, affecting the precision and quality of work. Whether it's for a residential mower or a commercial-grade machine, selecting the right spindle is crucial for optimal performance and durability. With a variety of options available, it's important to match the spindle to the machine's needs and the demands of the task at hand.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4