Introduction to BOPP Tape Slitting Machines

BOPP tape slitting machines are specialized equipment designed for the precise cutting of BOPP (Biaxially Oriented Polypropylene) tapes. These machines are integral to the packaging industry, facilitating the production of tape rolls of various widths and lengths. The BOPP tape slitting machine Taiwan market caters to a diverse range of industrial applications, from manufacturing plants to printing shops and retail sectors.

Types and Applications

The variety of BOPP tape slitting machines includes models suitable for different scales of operation and functionality. These machines are adept at handling various tasks, from simple slitting to more complex tape processing requirements. Their applications span across multiple industries, including food and beverage, commodities, and other packaged goods sectors, highlighting their versatility in meeting the demands of both domestic and international markets.

Features and Technical Specifications

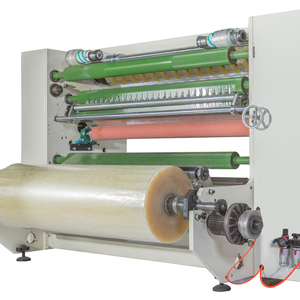

A BOPP tape slitting machine typically comes equipped with advanced features such as precision blades and tension control systems to ensure accurate slitting. The technical specifications may include various motor capacities, PLC (Programmable Logic Controller) systems, and engine types, each contributing to the machine's performance and efficiency. The design of these machines often focuses on user-friendliness, durability, and the ability to accommodate different tape sizes and materials.

Materials and Construction

The construction of a taiwanese BOPP tape slitting machine involves high-grade materials that ensure longevity and consistent performance. The use of robust metals and composites in the manufacturing process is standard, providing a sturdy framework and resistance to the wear and tear of industrial environments.

Advantages of Using BOPP Tape Slitting Machines

Utilizing a BOPP slitting machine offers numerous advantages, such as improved productivity due to its high-speed operations and minimal downtime. The precision engineering of these machines ensures reduced material wastage and enhanced roll quality, which is crucial for businesses looking to maintain efficiency and cost-effectiveness.

Choosing the Right Machine

Selecting the appropriate BOPP tape slitting machine from Taiwan requires consideration of several factors, including the intended application, desired tape dimensions, and production volume. Potential buyers are encouraged to assess the specifications and features of available machines to find a unit that aligns with their operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4