Introduction to Bottle Unscramble Systems

Bottle unscramble systems are integral components in the packaging industry, designed to efficiently organize and align bottles for filling, capping, and labeling processes. These systems are pivotal in ensuring seamless production lines, especially in sectors that handle high volumes of liquid products.

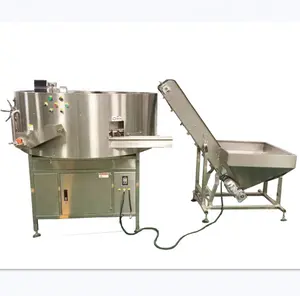

Types of Bottle Unscramblers

There is a diverse array of bottle unscrambler machines catering to various bottle shapes and sizes. The automatic bottle unscrambler is a popular choice for its precision and speed, while the plastic bottle unscrambler is tailored for plastic containers. For glass bottles, specialized unscramblers are employed to handle their fragility.

Applications and Features

Bottle unscramblers are versatile, finding applications across numerous industries including beverages, pharmaceuticals, and chemicals. The automatic high speed bottle unscrambler is particularly beneficial in environments where time and efficiency are paramount. These machines typically feature advanced controls and can integrate with other packaging machinery.

Materials and Advantages

Constructed from durable materials, bottle unscramblers are built to withstand the rigors of industrial environments. The use of stainless steel is common, providing resistance to corrosion and ease of cleaning. The advantages of using a pet bottle unscrambler machine include improved productivity, reduced labor costs, and enhanced accuracy in bottle orientation.

Choosing the Right Unscrambler

Selecting the appropriate unscrambler is crucial. Factors to consider include the type of bottles, production speed requirements, and compatibility with existing packaging lines. Machines like the omega unscrambler and new england machinery bottle unscrambler are renowned for their reliability and adaptability to different operational demands.

Maintenance and Parts

Maintaining a bottle unscrambler is essential for longevity and consistent performance. Availability of bottle unscrambler machine parts is a consideration for ongoing operations, ensuring minimal downtime and continuous productivity.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4