Understanding Busbars 18650 Battery Components

The busbars 18650 battery category encompasses a crucial range of components in the realm of power storage and distribution. Busbars themselves are conductive strips or bars, typically made of copper or aluminum, designed to distribute electricity with efficiency and minimal power loss. When associated with the 18650 battery format, these busbars are tailored to connect multiple lithium-ion cells, commonly used in various electronic applications due to their optimal balance of energy density and longevity.

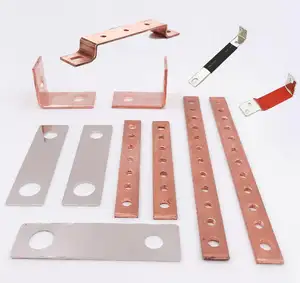

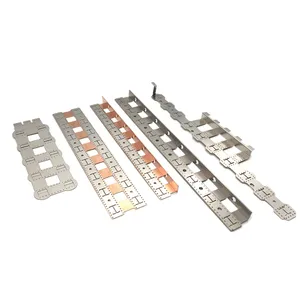

Types and Materials of 18650 Battery Busbars

The materials used in 18650 battery busbars are selected for their conductive properties and resistance to corrosion. Stainless steel and spring steel are popular choices, offering durability and reliable performance. The type of busbar can vary, with some designed for modular battery pack configurations, and others tailored for fixed installations. The choice of material and type directly impacts the efficiency and safety of the battery system.

Applications of Busbars in 18650 Battery Systems

Busbars for 18650 batteries are integral in applications requiring high-reliability power sources. These include renewable energy storage systems, electric vehicles, and large-scale portable electronics. The busbar's role in these systems is to ensure a stable connection between cells, which is vital for both the performance and safety of the battery pack.

Features and Advantages of 18650 Busbars

The design features of 18650 busbars include their compact size, which allows for efficient use of space within battery packs. Their robust construction also ensures longevity and resistance to mechanical stress. The advantages of using these busbars are manifold; they provide a low-resistance link between cells, which is essential for maintaining the battery's overall efficiency and temperature stability during high-load operations.

Selection Criteria for 18650 Battery Busbars

When selecting busbars for 18650 battery applications, it is important to consider the electrical and mechanical requirements of the system. The current-carrying capacity, thermal characteristics, and compatibility with the battery cells are critical factors. Additionally, the ease of integration into the battery management system (BMS) is a key consideration for ensuring overall system performance.

Environmental and Safety Considerations

Lastly, environmental and safety considerations are paramount when dealing with 18650 battery busbars. Materials used must not only be conductive but also environmentally benign and safe to handle. The design must account for fault conditions, ensuring that the busbars can withstand extreme conditions without compromising the integrity of the battery system.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4