Popular in your industry

Related Searches:

Top categories

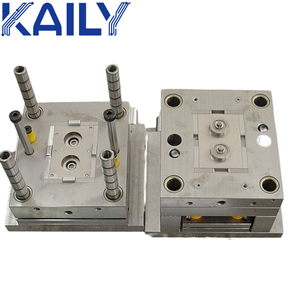

About cable plug mold

Introduction to Cable Plug Molds

Cable plug molds are essential components in the manufacturing of electrical connectors and cable assemblies. These precision tools are designed to shape and solidify materials into functional cable plugs used across various industries. The intricate process of creating a cable plug involves the careful selection of mold materials and design specifications to ensure the final product meets the required standards.

Types and Applications

The diversity of cable plug mold types is vast, catering to different connector shapes, sizes, and functionalities. From simple two-pin designs to complex multi-pin configurations, these molds are utilized in creating components for consumer electronics, automotive wiring harnesses, industrial machinery, and more. The application of these molds is critical in ensuring the reliability and efficiency of electrical connections in these devices.

Features and Materials

A cable plug mold must possess features that facilitate accurate replication and durability. The materials used range from hardened steel to aluminum, each offering distinct advantages in terms of heat resistance, longevity, and cost-effectiveness. The choice of material impacts the mold's performance, influencing the precision and quality of the cable plugs produced.

Advantages of Precision Molding

The advantages of using a cable plug mold in production are manifold. Precision molding ensures uniformity and consistency in mass-produced cable plugs, which is crucial for maintaining electrical safety and functionality. Additionally, the use of robust mold materials extends the lifespan of the mold itself, reducing the need for frequent replacements and thereby optimizing production cycles.

Customization and Standardization

Customization plays a pivotal role in the utility of a cable plug mold. Manufacturers can tailor molds to specific design requirements, ensuring that the end product aligns with the intended application. Conversely, standardization of certain mold elements, such as lift bars and clamp slots, can streamline the manufacturing process, enhancing compatibility and interchangeability across various mold designs.

Selecting the Right Mold

Choosing the right cable plug mold involves a thorough understanding of the intended application and the material properties. Suppliers on Alibaba.com offer a range of options and are equipped to provide guidance on mold selection without making absolute claims. By leveraging the platform's resources, buyers can make informed decisions to fulfill their specific cable plug production needs.