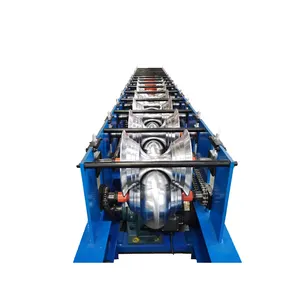

Introduction to Cap Iron Sheets

Cap iron sheets represent a versatile category of steel products known for their durability and wide range of applications. These sheets are commonly utilized in sectors that require robust materials, such as construction and manufacturing. The term 'cap iron sheet' typically refers to flat steel sheets that have been capped or coated, offering additional protection against environmental factors.

Types and Features

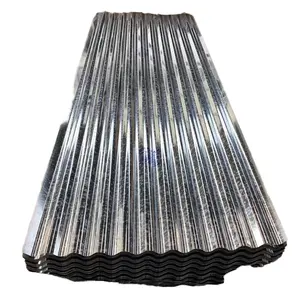

There are several types of cap iron sheets, each with unique features to suit different industry needs. The most common types include galvanized steel sheets, which are coated with a layer of zinc to prevent rusting, and hot rolled chequered steel products, known for their patterned surface which provides extra grip. These sheets come in various dimensions and thicknesses, tailored to the specific requirements of the application they are intended for.

Applications of Cap Iron Sheets

The application of cap iron sheets is extensive and diverse. In manufacturing plants, they are used in machinery parts due to their strength and durability. Garment shops utilize these sheets for fixtures and fittings that require a sleek, clean finish. Retail spaces also employ cap iron sheets in their displays and structural elements. The adaptability of these sheets makes them a preferred choice for both indoor and outdoor applications.

Material Composition and Advantages

Cap iron sheets are primarily made from steel, a material known for its strength and longevity. The capping process enhances these inherent qualities, providing additional benefits such as resistance to corrosion and increased structural integrity. These advantages make cap iron sheets a cost-effective solution for long-term projects and applications that demand high durability.

Environmental Impact and Sustainability

Sustainability is a crucial aspect of modern materials, and cap iron sheets contribute positively in this regard. The steel used in these sheets is often recyclable, which reduces the environmental footprint. Additionally, the capping materials are selected based on their eco-friendly properties, ensuring that the sheets are not only durable but also kinder to the environment.

Choosing the Right Cap Iron Sheet

Selecting the appropriate cap iron sheet for your project is essential. Factors to consider include the specific application, environmental conditions, and the physical stresses the sheet will need to withstand. While Alibaba.com does not manufacture or sell these products directly, the platform offers a comprehensive listing of suppliers who provide a wide range of options to meet various industrial requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4