Popular in your industry

Related Searches:

Top categories

About carbon fiber honeycomb panels

In an era where efficiency and sustainability are at the forefront of industrial innovation, carbon fiber honeycomb panels are revolutionizing the way businesses approach material strength and weight reduction. This guide delves into the myriad of features and benefits that these advanced materials offer, particularly their application in enhancing performance across various industries. From their intricate construction involving a honeycomb core to their exceptional strength-to-weight ratio, carbon fiber honeycomb panels are not just a product but a pivotal investment in the future of manufacturing, construction, and design. As we explore their composition, manufacture, and diverse applications, businesses stand to gain a competitive edge by leveraging the unparalleled advantages these panels provide.

Understanding Carbon Fiber Honeycomb Panels

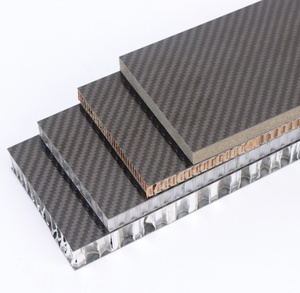

Carbon fiber honeycomb panels are recognized for their lightweight yet robust construction, primarily utilizing a honeycomb core. This core is integral to the panel's design, functioning similarly to an I-Beam, where the honeycomb acts as the web and the carbon fiber skins as the flanges. This configuration not only enhances the panel's torsional rigidity but also significantly increases its stiffness as the core thickness grows. The unique composition of the honeycomb, made from aramid fiber paper coated with a heat-resistant resin, contributes to its resilience, low density, and strength-to-weight ratio.

The panels are designed with a lay-up of 0/90 uni-directional twill weave face sheets, each side featuring approximately 0.03 inches of carbon, encapsulating the honeycomb core. This structure is engineered to provide additional compressive strength at lower densities compared to foam cores, while also offering moisture resistance, energy absorption, and sound and vibration dampening properties. A critical aspect of these panels is the bond quality between the honeycomb core and the carbon fiber skin. Proper bonding is crucial since it ensures the structural integrity of the panel by preventing the skin from peeling away from the core. High-quality fillets are formed to transmit loads effectively from the skins into the core, which is essential for maintaining the panel's durability.

The Composition and Manufacture of Carbon Fiber Honeycomb Panels

Carbon Fiber/Honeycomb Sandwich Panels are engineered by integrating a honeycomb core with layers of carbon fiber prepreg. This combination leverages the core's lightweight attributes and the carbon fiber's strength, resulting in panels that exhibit superior strength-to-weight ratios. The carbon fiber prepreg contributes to the panel's structural integrity, offering benefits such as thermal and electrical conductivity, high tensile strength, and excellent fatigue resistance without adding unnecessary weight.

The manufacturing process involves curing the panels at high temperatures and pressures, ensuring that the carbon fiber skins are fully consolidated and firmly adhered to the honeycomb core. This method prevents the honeycomb cells from being filled with resin, maintaining the panel's lightness. The honeycomb core itself is selected for its high compressive strength and low density, with an emphasis on its bondable properties to preserve the panel's structural integrity.

To customize the stiffness of the panel, variations in core thickness can be employed, allowing for a tailored approach to strength without significantly impacting the panel's weight or cost. This adaptability makes the carbon fiber honeycomb panels suitable for a diverse range of applications where specific performance criteria are paramount.

Types of Carbon Fiber Honeycomb Panels Available on Alibaba.com

Alibaba.com showcases a diverse range of carbon fiber honeycomb panels tailored for various applications and industries. These panels are constructed with a unique honeycomb core design, sandwiched between layers of carbon fiber, offering a blend of strength and lightweight properties. The assortment includes options designed for electromagnetic compatibility and structural integrity.

For aesthetic applications, the platform offers Decorative Wall Panels, including sandwich wall panels from various suppliers, which combine visual appeal with functional benefits. In the realm of high-strength, lightweight solutions, the carbon fiber sheets, plates, and boards available are manufactured to meet industry-specific requirements, ensuring a fit for purpose product for buyers.

The acoustic performance is addressed through products ideal for sound management in both commercial and residential settings. Customization options are also highlighted, with products that can be tailored in finish, from glossy to matte, and in dimensions to suit specific project needs.

For industries demanding the highest durability, Alibaba.com lists carbon fiber honeycomb panels with cores known for their exceptional strength-to-weight ratio. These are complemented by a variety of core materials such as foam, PP, and aluminum, each bringing its own set of advantages to the table, depending on the application requirements.

Key Features of Carbon Fiber Honeycomb Panels

Carbon fiber honeycomb panels are renowned for their exceptional strength-to-weight ratio, achieved through a unique composition that includes a honeycomb core. This core, made from aramid fiber paper coated with heat-resistant resin, contributes to the panel's resilience and low density. The structure of these panels is akin to an I-Beam, where the honeycomb acts as the web and the carbon fiber skins function as flanges. This design not only enhances the panel's torsional rigidity but also significantly increases its stiffness as the core thickness grows.

The honeycomb core distinguishes itself by offering additional compressive strength at lower densities compared to low-density foam cores, while also providing benefits such as moisture resistance, energy absorption, and sound and vibration dampening. The lay-up design typically features a 0/90 uni-directional twill weave face sheet, with a balanced thickness of carbon on each side of the core. The quality of the bond between the honeycomb and the carbon fiber skin is crucial for maintaining the structural integrity of the panel. A well-formed fillet is essential for transmitting loads effectively from the skins into the core, preventing the skins from peeling away.

Lightweight Yet Strong

Carbon Fiber/Honeycomb Sandwich Panels exemplify a fusion of strength and lightness, achieved by integrating an aramid honeycomb core between carbon fiber prepreg layers. This core acts as a separator, enhancing the panel's strength beyond the capabilities of the carbon fiber skins alone. The use of medium modulus carbon fiber for the outer layers contributes to a high strength-to-weight ratio, characterized by features such as impressive tensile strength, reduced density, and minimal thermal expansion. The panels maintain their lightweight attribute due to the honeycomb core's resistance to resin filling, ensuring no unnecessary weight from excess resin.

The structural integrity of these panels is further reinforced by the high bondable properties of the aramid honeycomb core, which also contributes to a higher compressive strength and a lighter core compared to alternatives like balsa or foam cores. To augment the stiffness without significantly impacting weight and cost, a thicker core can be utilized. The result is a panel that offers a remarkable balance of lightness and strength, suitable for applications where both properties are highly valued.

Enhanced Durability and Longevity

Carbon Fiber/Honeycomb Sandwich Panels are engineered for enhanced durability and longevity. The integration of an aramid honeycomb core between carbon fiber skins results in panels that exhibit superior strength characteristics compared to the individual materials. The carbon fiber prepreg outer layers contribute to the panel's robustness, offering impressive tensile strength and fatigue resistance. This composition ensures that the panels can withstand demanding conditions without compromising their structural integrity.

The manufacturing process, which involves curing at high temperatures and pressures, ensures that the carbon fiber skins are fully consolidated and firmly bonded to the honeycomb core. This method prevents the honeycomb cells from filling with resin, maintaining the panel's low weight and preventing any unnecessary increase in resin weight that could affect durability. Additionally, the aramid honeycomb core is selected for its high bondable properties, which further secures the panel's longevity.

For applications requiring even greater stiffness, a thicker core can be utilized, which remarkably does not substantially increase the panel's weight or cost. This adaptability in design allows for the creation of panels that meet specific durability requirements without sacrificing performance. The result is a product that offers a balance of lightweight characteristics with the strength needed for long-term use in various applications.

Applications in Various Industries

Carbon Fiber/Honeycomb Sandwich Panels are engineered for use in environments that demand high strength-to-weight ratios and robust performance. The unique construction of these panels, involving an aramid honeycomb core sandwiched between carbon fiber skins, contributes to their superior strength properties compared to the skins alone. This design not only enhances the panel's strength but also maintains a low weight, making them suitable for applications where weight savings are critical.

The panels' carbon fiber prepreg outer layers are notable for their high tensile strength, thermal and electrical conductivity, and excellent fatigue resistance. These characteristics are essential in applications that require materials to withstand high levels of stress while maintaining structural integrity. The aramid honeycomb core offers higher compressive strength and lower densities, which is advantageous in industries where durability and performance are paramount.

Due to their impressive strength and lightweight nature, these panels are particularly well-suited for use in the aerospace and automotive sectors, where they contribute to fuel efficiency and overall performance. Additionally, their robustness and resistance to thermal expansion make them ideal for architectural and construction applications, where long-lasting and reliable materials are necessary. The versatility of carbon fiber honeycomb panels makes them a valuable component across various industries, fulfilling a range of structural requirements.

Aerospace and Automotive Sectors

Carbon Fiber/Honeycomb Sandwich Panels are engineered to meet the demanding requirements of the aerospace and automotive sectors. These panels are constructed by integrating an aramid honeycomb core with carbon fiber prepreg skins. This unique composition results in panels that exhibit superior strength without the penalty of added weight, a critical factor in both aerospace and automotive design. The inherent strength of the carbon fiber and the geometric rigidity provided by the honeycomb structure contribute to the panels' ability to withstand the stresses encountered in high-performance environments.

The use of medium modulus carbon fiber for the outer layers of the panel ensures a high strength-to-weight ratio, essential for applications where every gram counts. This material choice also provides benefits such as thermal and electrical conductivity, high tensile strength, and excellent fatigue resistance. These properties are particularly beneficial in the aerospace industry, where materials must endure the rigors of flight and the automotive sector, where durability and performance are paramount.

Moreover, the manufacturing process of these panels involves curing at high temperatures and pressures, ensuring that the carbon fiber skins are fully consolidated and bonded to the aramid honeycomb core. This process eliminates the risk of the honeycomb cells filling with resin, which could otherwise add unnecessary weight and compromise the structural integrity. The ability to customize the core thickness allows for an increase in stiffness without a significant increase in weight, offering design flexibility to meet specific industry needs.

Architectural and Construction Uses

Carbon Fiber/Honeycomb Sandwich Panels offer a revolutionary solution in the field of architecture and construction. Their unique composition, which involves an aramid honeycomb core sandwiched between carbon fiber skins, provides a synergy that leverages the strength properties of both materials. The panels are known for their impressive strength-to-weight ratio, a critical factor in modern architectural designs that aim for both durability and minimalism.

The manufacturing process ensures that the carbon fiber skins are fully bonded to the honeycomb core, maintaining the structural integrity of the panels without adding unnecessary weight. This is particularly beneficial in construction, where the balance between weight and strength is paramount. The aramid honeycomb core contributes to higher compressive strength and lower core densities, which is advantageous when constructing buildings that require lightweight yet strong materials.

Moreover, the adaptability of these panels is evident in their ability to be customized for specific applications. A thicker core can be used to increase stiffness without a significant increase in weight or cost, allowing for tailored solutions in architectural projects. This customization potential makes Carbon Fiber/Honeycomb Sandwich Panels a versatile choice for innovative construction needs.

Benefits for Businesses Investing in Carbon Fiber Honeycomb Panels

Carbon fiber is recognized in the construction industry for its strength, light weight, and cost-effectiveness. These attributes contribute to its growing acceptance as a material that can offer significant benefits to businesses. The investment in carbon fiber, particularly in its honeycomb panel form, can lead to reduced maintenance costs due to its durability.

The material's lightweight nature, coupled with its robustness, allows for meeting close tolerance requirements, facilitating easy and quick installation processes. This can result in labor cost savings and expedited project timelines.

Moreover, the sustainability aspect of carbon fiber is noteworthy. While the manufacturing process is energy-intensive, the use of green energy sources can mitigate environmental impacts, making it a more sustainable option compared to traditional materials. This can be particularly appealing for businesses looking to enhance their environmental stewardship and reduce their carbon footprint.

The potential for recycling and the use of biodegradable variants add to the material's benefits, offering a greener footprint for businesses concerned with sustainability. These factors combined make carbon fiber honeycomb panels a forward-thinking choice for businesses aiming to invest in innovative, efficient, and environmentally responsible materials.

Cost-Effectiveness and ROI

Carbon fiber honeycomb panels offer a balance of strength and lightness, which translates into cost-effectiveness for businesses. The use of honeycomb core material with its low density and high compressive strength, results in a product that is lighter than many alternative core materials, such as closed cell PVC foam. This reduction in weight can lead to significant savings in transportation and handling costs. Moreover, the durability of these panels means they have a longer lifespan, reducing the need for frequent replacements and thus offering a better return on investment over time.

The adaptability of honeycomb to various manufacturing processes, including wet-lay, vacuum bagging, and adhesive bonding, allows for customization without a substantial increase in production costs. This versatility ensures that the panels can be tailored to specific industry needs while maintaining cost efficiency. Additionally, the ease of handling and bonding due to the small cell size and sturdy wall thickness of the honeycomb structure simplifies the manufacturing process, potentially lowering labor costs.

In terms of environmental impact, the lightweight nature of carbon fiber honeycomb panels can contribute to energy savings, especially in the transportation and automotive sectors where reduced weight leads to improved fuel efficiency. This aspect not only enhances the sustainability profile of the product but also aligns with the growing demand for eco-friendly materials in various industries, potentially opening up new market opportunities for businesses.

Sustainability and Environmental Impact

Recycled carbon fiber composite sheets exemplify sustainability in material innovation. These sheets are crafted using recycled carbon fiber, which not only gives a new life to carbon fiber but also reduces waste. The use of biobased epoxy resin in the composition underscores an eco-friendly approach, moving away from purely petroleum-based products. Organic pigments add color without the heavy environmental footprint of synthetic dyes. The manufacturing process itself is conscientious of energy consumption, utilizing renewable energy sources to forge these materials under high pressure and heat. This method reflects a commitment to reducing carbon emissions and promoting a greener production cycle. The result is a material that is not only lightweight and durable but also aligns with the growing demand for environmentally responsible manufacturing practices. The potential applications of this material are diverse, indicating its adaptability and the possibility for widespread use in various industries, which further supports the sustainability narrative by potentially reducing the environmental impact across multiple sectors.

Conclusion

Carbon fiber honeycomb panels represent a pinnacle of material engineering, offering a symphony of strength, durability, and lightweight properties that are unmatched by traditional materials. Throughout this article, we've explored the intricate design of these panels, which feature a honeycomb core and carbon fiber skins, resulting in a product that boasts superior torsional rigidity and compressive strength. The versatility of these panels is evident in their wide range of applications, from the aerospace and automotive sectors to architectural and construction projects, where they contribute to enhanced performance and sustainability. Businesses investing in these panels can expect not only a significant return on investment due to their durability and low maintenance but also a step forward in environmental responsibility through potential energy savings and the use of recycled and biodegradable materials. As industries continue to seek innovative solutions that balance efficiency with ecological impact, carbon fiber honeycomb panels stand out as a smart and strategic choice for a sustainable future.