Popular in your industry

Top categories

About card collator

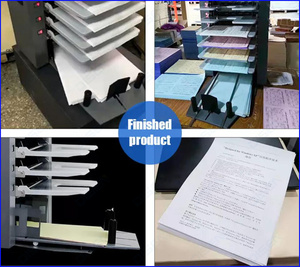

Introduction to Card Collators

Card collators are integral components in the paper processing and packaging industries, designed to streamline the production of paper goods. These machines are adept at organizing, counting, and stacking various paper products, ensuring efficiency in operations ranging from small-scale setups to large manufacturing plants.

Types and Applications

The versatility of card collators extends across various applications, including the production of toilet papers, napkins, paper cups, and serviettes. Their use is prevalent in settings such as hospitality, large-scale paper mills, and specialized paper product manufacturing facilities. The choice of a card collator can be tailored to the specific needs of a business, with options suitable for different production volumes and operational scales.

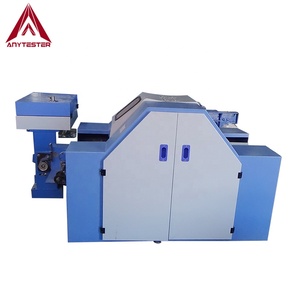

Features and Functionality

A standard card collator is equipped with multiple units that perform tasks such as embossing, slitting, folding, and counting. The embossing process can be customized using various patterns, achieved through steel-to-steel or steel-to-rubber embossing rollers. Advanced models feature color printing capabilities, enhancing the aesthetic appeal of the final product. The integration of photoelectric technology allows for real-time monitoring of the machine's functions, alerting operators to paper shortages or operational issues.

Machine Specifications

Card collators come in different sizes, with smaller machines typically weighing around 1,000kgs and consuming power of 3kw or more, capable of producing 70 to 80 pieces per minute. Larger variants can weigh in excess of 3,000kgs, boasting production capacities of approximately 150 meters per minute, which translates to about 3 tons of paper products daily. These robust machines are often fully automated, featuring pneumatic systems and PLC control panels for seamless operation.

Automation and Control

The operational efficiency of card collators is significantly enhanced by automation. Most machines come with automatic oil lubrication systems and utilize either gear or chain driving mechanisms. The incorporation of PLC control panels facilitates full automation, allowing for precise control over the production process and reducing the need for manual intervention.

Choosing the Right Card Collator

Selecting the appropriate card collator is crucial for optimizing production efficiency. Factors to consider include the machine's weight, power usage, production capacity, and the specific paper products intended for manufacture. Prospective buyers can explore a range of card collator options on Alibaba.com, each designed to meet various production demands without compromising on functionality or efficiency.