Introduction

In the realm of filtration technology, cartridge filters have emerged as a versatile and efficient solution for various industries. These tubular devices, available in surface and depth filter types, are designed to remove contaminants, particles, and chemicals from liquids. This article delves into the intricacies of cartridge filters, exploring their types, working principles, and optimization techniques. We will also discuss how to unlock their full potential, their advanced applications, and their role in promoting sustainability. Join us as we navigate the world of cartridge filters, their maintenance, and their impact on our environment.

Understanding Cartridge Filters

Cartridge filters are tubular filtration devices used across various industries to remove unwanted contaminants, particles, and chemicals from liquids. They are housed in filter housings or casings, and their optimal contamination level should be less than 0.01% by weight. There are two basic types of cartridge filters: Surface filters and Depth filters. Surface filters restrict the passage of suspended solids and contaminants on the surface, while depth filters retain suspended solids within their multiple layers or thicker media.

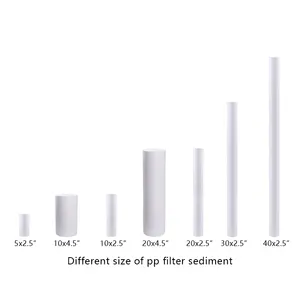

Types of Cartridge Filters

Cartridge filters are categorized into two types: Surface filters and Depth filters. Surface filters restrict the passage of suspended solids on the surface, while Depth filters retain solids within the media. There are various types of cartridge filters, including Wound, Melt Blown, Air Filter, Pleated, Sintered, and Wire Mesh Cartridge Filters. Each type has a unique construction process and application, offering different filtration efficiencies and lifespans. For instance, Sintered filters are robust, corrosion-resistant, and can withstand high temperatures and pressures.

How Cartridge Filters Work

Cartridge filters operate differently from granular media filters, functioning via surface filtration rather than deep filtration. They can trap small or large impurities without needing sand of different grain sizes. The filtration quality of the cartridge filter is less dependent on the water speed, filtering efficiently at both slow and fast speeds. Each element of this filter does not require backwashing, and they become more efficient as they clog. The debris are automatically distributed over the whole surface, with the water seeking the quickest route.

Unlocking the Power of Cartridge Filters

High-capacity pleated cartridges offer maximum dirt holding capacity and micron retention ratings to 0.5 at beta 5000 or 99.98 percent efficiency. These cartridges are designed with a unique 'Y' pleat arrangement, maximizing effective surface area and dirt containment. This design extends the cartridge's life and increases productivity, leading to fewer cartridge change-outs and lower replacement costs. The cartridges are made with high-quality materials and advanced manufacturing processes, ensuring high efficiency performance.

Optimizing Filter Efficiency

Optimizing the efficiency of your cartridge pool filter involves regular maintenance and cleaning. Using a granular filter cleaner regularly can help cleanse the pleats clogged with minerals or oily residue. Additionally, adding a pool clarifier can enhance the filter's performance by clumping tiny particles into larger ones, making them easier to filter. However, be cautious not to overdose as it can cause cloudiness. Lastly, a small amount of a high-quality filter fiber product can help trap more fine dirt and debris. Remember, proper maintenance can prolong the life of your filter cartridges and keep your pool water clean and clear.

Maintenance and Cleaning Techniques

Maintaining and cleaning cartridge filters is crucial for their longevity and efficiency. Start by turning off the pump and removing the filter housing. Rinse the filters with moderate pressure from a garden hose, focusing on flushing debris from between the pleats. Submerge the filters in a TSP solution overnight, then rinse off any loosened debris. For filters with mineral residue, a muriatic acid bath can help clean it. After a final rinse, reinstall the filters. Regular maintenance and cleaning can significantly extend the life of your cartridge filters and keep your pool in optimal condition.

Advanced Applications of Cartridge Filters

Leading innovators in the industry have developed an innovative cleaning solution for cartridge filters used in water treatment facilities. This advanced application involves a cleaning-in-place method using specialized membrane cleaners. The new method prevents the need for frequent cartridge filter replacements, reducing plastic waste and contributing to sustainability goals. This process optimizes plant performance, results in financial savings, and offers environmental benefits. This innovation represents a significant advancement in the application of cartridge filters in water treatment facilities.

Industrial Use Cases

Cartridge filters find extensive use in various industrial applications. For instance, pleated filters, known for their high flow rates and efficient filtration, are commonly used in industrial water filtration and HVAC systems. Membrane filters, which offer high purity levels, are often used in pharmaceuticals, biotechnology, and food and beverage processing. Activated carbon filters are popular in water and air purification, and gas processing applications. High-temperature and high-pressure applications often employ stainless steel cartridge filters, such as in oil and gas filtration, chemical processing, and water treatment.

Environmental Impact and Sustainability

Cartridge filters are an essential tool for smart and sustainable pool operation. They offer significant advantages over granular media filters in terms of efficiency, filtration quality, and maintenance. Notably, they enable real savings on water, electricity, and treatment products, contributing to a more sustainable and eco-friendly pool system. Well-maintained cartridges can last four to six years, reducing the need for frequent replacements and thus minimizing environmental impact. The cartridge filter is indeed a key piece of equipment for a smart and sustainable pool, improving operation and reducing overall ecological impact.

Conclusion

Cartridge filters have proven to be a game-changer in the filtration industry, offering efficient and versatile solutions for various applications. From their basic understanding to their types and working principles, we've seen how these filters can be optimized for maximum efficiency. The advanced applications of cartridge filters, particularly in water treatment facilities, have demonstrated their potential for innovation and sustainability. Their extensive use in industrial applications underscores their versatility, while their contribution to environmental sustainability highlights their role in promoting eco-friendly practices. Regular maintenance and cleaning can significantly extend the life of these filters, ensuring optimal performance and longevity. As we continue to strive for efficiency and sustainability, the cartridge filter stands as a testament to the power of smart design and innovation.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4