Introduction to Casting Train Wheels

Casting train wheels are a critical component in the railway industry, serving as the foundational element that interfaces with the rail tracks to support and move rolling stock. These wheels are produced through a process known as casting, where molten metal is poured into a mold to achieve the desired shape. This category encompasses a variety of wheels designed to meet the diverse needs of the rail transport sector.

Types and Applications

There are several types of casting train wheels tailored for different applications, including freight, passenger, and high-speed trains. Each type is engineered to withstand varying loads, speeds, and track conditions. The applications of these wheels extend beyond locomotives to encompass wagons, coaches, and other rail-bound vehicles.

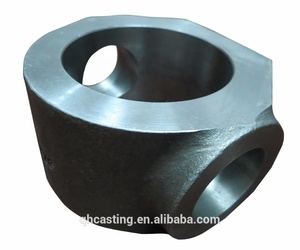

Features and Materials

The features of casting train wheels include their robust design and durability. Materials used in the casting process typically involve high-grade steel or iron alloys, chosen for their wear resistance and strength. The selection of material contributes significantly to the wheel's performance and safety.

Advantages of Cast Wheels

The advantages of using cast train wheels include their ability to be customized to specific requirements and their cost-effectiveness for large-scale production. Additionally, the casting process allows for intricate designs that can enhance the wheel's functionality and lifespan.

Manufacturing Process

The manufacturing process of casting train wheels involves several stages, from mold design to the actual casting and subsequent cooling. Quality control is paramount throughout the process to ensure that each wheel meets the stringent standards required for railway components.

Considerations for Buyers

Buyers looking for casting train wheels should consider factors such as wheel size, load capacity, and material properties. It is essential to source wheels that are compatible with the intended rail system and that comply with relevant industry standards.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4