All categories

Featured selections

Trade Assurance

Buyer Central

Help Center

Get the app

Become a supplier

(5 products available)

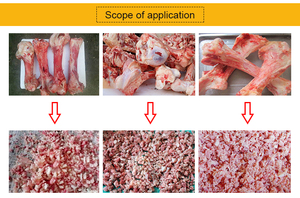

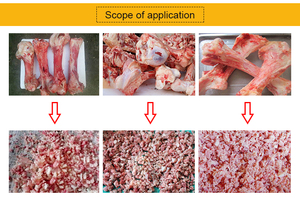

Cattle bone paste maker machine serve as essential components in the realm of food processing, particularly in the meat industry. These machines are designed to handle various tasks involved in the preparation and processing of meat products. From grinding and mixing to slicing and tenderizing, cattle bone paste maker machine ensure efficiency, consistency, and hygiene in meat production. They are built to withstand rigorous use, often constructed from durable materials like stainless steel, which is resistant to rust and easy to clean. As the demand for processed meat products continues to grow, the role of cattle bone paste maker machine becomes increasingly vital in meeting the needs of large-scale production facilities.

The category of cattle bone paste maker machine encompasses a diverse range of machinery, each designed for specific functions within meat processing. Common types include meat grinders, meat slicers, and meat mixers. Meat grinders are essential for breaking down large pieces of meat into finer textures, suitable for products like sausages and ground beef. Meat slicers offer precision in cutting, enabling uniform slices for deli meats and other products. Meat mixers are used to incorporate seasonings and other ingredients evenly throughout the meat mixture. Each type of cattle bone paste maker machine is engineered to optimize specific stages of the meat processing workflow, ensuring quality and consistency in the final product.

cattle bone paste maker machine are equipped with various features that enhance their functionality and efficiency. Many machines offer adjustable settings that allow operators to control the size and texture of the meat output. Safety features, such as emergency stop buttons and protective guards, are standard to prevent accidents during operation. Additionally, some cattle bone paste maker machine come with automated cleaning systems, reducing downtime and maintaining hygiene standards. The ability to handle large volumes of meat with consistent results makes these machines indispensable in high-demand environments. Advanced models may also integrate digital controls for precision and ease of use, further streamlining the meat processing process.

The construction of cattle bone paste maker machine is critical to their performance and longevity. Most machines are made from stainless steel due to its durability, resistance to corrosion, and ease of cleaning. Stainless steel surfaces are non-porous, which helps prevent the growth of bacteria and ensures compliance with food safety regulations. In addition to stainless steel, some components may be made from food-grade plastics or other materials that meet safety standards. The design of cattle bone paste maker machine often includes easily detachable parts, allowing for thorough cleaning and maintenance. This construction ensures that the machinery can withstand the harsh conditions of industrial food processing environments.

Proper use of cattle bone paste maker machine is essential for maximizing their benefits and ensuring safe operation. Operators should be trained in the specific functions and safety protocols of each machine. It's crucial to regularly inspect and maintain cattle bone paste maker machine to prevent malfunctions and ensure optimal performance. When using these machines, operators should wear appropriate protective gear, such as gloves and aprons, to minimize risk. It's also important to follow manufacturer guidelines regarding capacity limits to avoid overloading the machinery, which can lead to damage or inconsistent results. By adhering to these guidelines, operators can ensure that cattle bone paste maker machine function efficiently and safely, contributing to high-quality meat processing outcomes.

When selecting cattle bone paste maker machine , it's essential to consider the specific needs of your meat processing operation. Factors such as the type of meat being processed, the desired output, and the scale of production play crucial roles in determining the right machinery. It's important to assess the capacity requirements to ensure the machinery can handle the volume of meat being processed. Additionally, consider the adaptability of cattle bone paste maker machine to different processing tasks, such as grinding, slicing, or mixing, to maximize efficiency and versatility.

Another critical aspect is the technological features integrated into cattle bone paste maker machine . Advanced models offer digital controls and automation capabilities that enhance precision and reduce manual labor. Look for machinery with user-friendly interfaces and programmable settings, which can streamline operations and improve consistency. Safety features, such as emergency stop buttons and protective guards, should also be a priority to ensure safe operation. Evaluating these features will help in choosing cattle bone paste maker machine that align with the operational goals and safety standards of your facility.

The size of cattle bone paste maker machine should be based on the volume of meat you plan to process and the available space in your facility. Consider the throughput capacity and dimensions to ensure it fits seamlessly into your production line. It's also important to factor in future growth plans, as investing in slightly larger machinery may accommodate increased production demands over time.

Regular maintenance of cattle bone paste maker machine is crucial to ensure longevity and optimal performance. This includes routine cleaning, lubrication, and inspection of parts to prevent wear and tear. Establishing a maintenance schedule and training staff on proper procedures can help identify issues early and reduce downtime. Additionally, sourcing replacement parts from reputable suppliers ensures the machinery remains in good working condition.

Yes, certifications for cattle bone paste maker machine can indicate compliance with industry standards and safety regulations. Look for machinery that meets relevant certifications such as ISO, CE, or local food safety standards. These certifications often reflect the quality and reliability of the machinery, providing assurance that it meets necessary guidelines for safe and efficient meat processing.

Customization options for cattle bone paste maker machine are available from many manufacturers, allowing for modifications to fit specific processing requirements. This can include adjustments to size, capacity, or specific components to better suit particular types of meat or processing techniques. Working with manufacturers to tailor machinery ensures it aligns perfectly with operational needs and enhances productivity.

For issues with cattle bone paste maker machine , start by checking the power supply and ensuring all connections are secure. Inspect the machinery for blockages or worn parts that may affect performance. Refer to the manufacturer's manual for guidance on troubleshooting specific problems. Regular training for operators can also help them identify and resolve common issues quickly, minimizing disruption to the production process.