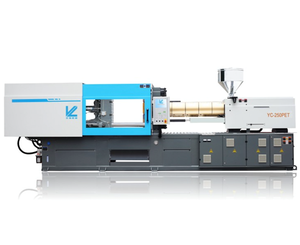

Introduction to Plastic Injection Moulding Machines

Plastic injection moulding machines are pivotal in the manufacturing sector, offering a pathway to produce a vast array of plastic parts with precision and efficiency. These machines are the backbone of production lines, catering to various industries from consumer electronics to packaging. A cheap plastic injection mould machine can be a cost-effective solution for businesses looking to maintain competitiveness without compromising on the quality of their plastic components.

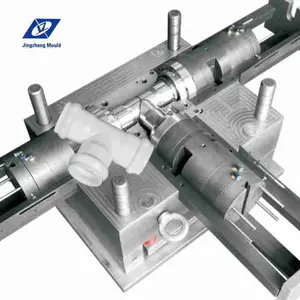

Types and Applications

The versatility of plastic injection moulding equipment is evident in its wide range of applications. From creating intricate medical devices to robust automotive parts, these machines adapt to the demands of different sectors. The adaptability extends to the production of PVC pipe fittings and thin-wall containers, highlighting the machine's capability to handle both rigid and flexible materials with ease.

Features and Materials

A durable plastic injection moulder is engineered to withstand the rigors of continuous operation. The integration of a special screw design enhances the plasticizing shot weight and speed, ensuring efficient processing of granules into desired shapes. Materials used in the construction of these machines, such as reinforced steel, contribute to their longevity and consistent performance.

Advantages of Modern Moulding Machines

Investing in a modern plastic injection moulding machine brings several advantages. The single-cylinder system with a servo-valve ensures a swift response rate during operation, reducing the likelihood of defects. Clamping forces that range significantly allow for precise resistance against external machining forces, ensuring the production of components meets industry standards.

Design and Precision

The design of a cost-effective plastic injection moulder focuses on precision. With advanced clamping units featuring steel bushings, these machines minimize wear resistance and the need for lubrication, leading to cost savings in maintenance. The precise clamping force is tailored to the specific requirements of the task, ensuring that each product is moulded with accuracy.

Choosing the Right Machine

Selecting the right plastic injection moulding machine is crucial for your production needs. Alibaba's platform connects you with a variety of machines that cater to different sizes of preforms and applications. By browsing through the listings, you can find the machine that aligns with your operational requirements and enhances your production capabilities.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4