Popular in your industry

Related Searches:

Top categories

About chitosan production line

Understanding the Chitosan Production Line

Chitosan, a versatile biopolymer derived from chitin, is predominantly found in the shells of crustaceans. It is gaining prominence due to its biodegradability, biocompatibility, and non-toxicity. A chitosan production line refers to the comprehensive set of equipment and processes designed to extract and refine chitosan from natural sources. This introduction delves into the intricacies of these production lines, their types, applications, and the features that set them apart.

Types of Chitosan Production Equipment

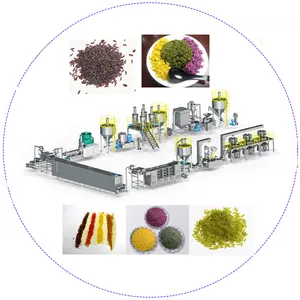

The equipment used in a chitosan production line varies based on the source of chitin and the desired properties of the chitosan. Common types include deacetylation units, drying systems, and milling equipment. Each component plays a crucial role in ensuring the integrity of the chitosan produced, whether for industrial, pharmaceutical, or agricultural use.

Applications of Chitosan

Chitosan's applications are diverse, ranging from water treatment to medical applications, food preservation, and agricultural enhancements. The design of a chitosan production line is often tailored to the end-use of the product, ensuring that the chitosan's molecular weight and degree of deacetylation match its intended application.

Features of Chitosan Production Lines

A high-efficiency chitosan production line is characterized by its automation level, precision in control systems, and energy efficiency. These features contribute to the consistency of the final product's quality. Additionally, the adaptability to handle different volumes and qualities of raw materials is a testament to the robustness of the production line.

Materials and Advantages of Chitosan Production

The primary raw material for chitosan production is chitin, which is sustainably sourced from shellfish waste, thus contributing to waste reduction. The chitosan production line is designed to maximize yield and purity of the final product, while minimizing environmental impact, making it a cornerstone in sustainable manufacturing practices.

Choosing the Right Chitosan Production Line

Selecting an appropriate chitosan production line involves considering the scale of production, end-product specifications, and the efficiency of the process. While Alibaba.com does not endorse any specific brand or manufacturer, the platform offers a gateway to a wide array of suppliers, each providing detailed information about their equipment and technology to aid in making an informed decision.