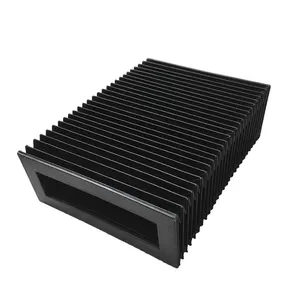

CNC Flexible Accordion Covers: An Overview

CNC flexible accordion covers are essential components in the protection of CNC machines. These covers are designed to safeguard the mechanical parts of CNC equipment from contaminants such as dust, chips, and accidental spills, which can affect the machine's performance and longevity.

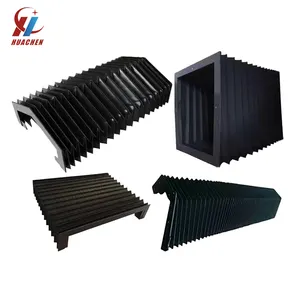

Types and Applications

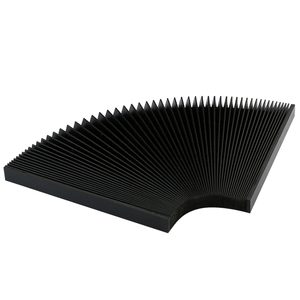

There is a diverse range of cnc flexible accordion covers tailored to various machine types and applications. From horizontal to vertical machine orientations, these covers are adaptable to multiple axes. Their applications span across industries, from automotive to aerospace, ensuring the smooth operation of CNC machines in different manufacturing environments.

Features and Materials

The construction of cnc flexible accordion covers involves durable materials like polyurethane-coated fabric or elastomer-coated polyester. These materials are selected for their wear resistance and ability to withstand harsh conditions. The design features include collapsible folds that compress when the machine is in motion and extend to provide complete coverage during operation.

Advantages of Using CNC Flexible Accordion Covers

Utilizing cnc flexible accordion covers brings several advantages to the workplace. They extend the life of CNC machines by preventing the ingress of harmful elements, thus reducing maintenance costs. Additionally, they contribute to the safety of the operation by minimizing the risk of accidents caused by flying debris.

Selection Criteria

When selecting a cnc flexible accordion cover, consider the size, shape, and movement patterns of your CNC machine. It's crucial to choose a cover that fits the specific dimensions and motion range to ensure maximum protection without hindering the machine's functionality.

Integration with CNC Systems

Modern cnc flexible accordion covers are designed to integrate seamlessly with CNC systems. They are engineered to withstand the rapid movements and complex operations of CNC machinery, ensuring that they do not disrupt the precision and efficiency of the manufacturing process.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4