Popular in your industry

Related Searches:

Top categories

About cnc tile machine

CNC tile machines are computerized numerical control machines used to automate the process of cutting and shaping tiles. A CNC tile machine processes tiles into precise shapes and sizes, enhancing efficiency and accuracy in the tiling industry. The CNC tile cutting machine uses advanced software and cutting tools to execute intricate designs on various types of tiles, making it a valuable tool in the construction and renovation sectors.

The types of CNC tile machines

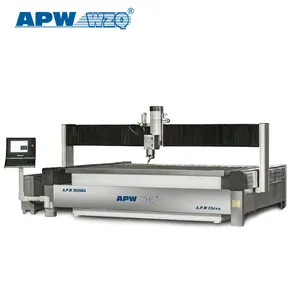

There are several types of CNC tile machines, each designed for specific applications based on the size and material of the tiles. Some machines are suited for cutting, engraving, or polishing tiles. The most common type is the CNC tiling router, which uses a rotating cutting tool to precisely shape and create designs on tiles. Another type is the waterjet CNC machine, which utilizes a high-pressure water stream mixed with abrasive materials to cut through hard tiles. Laser CNC machines are also used for precise and intricate tile cutting using a focused laser beam. For larger scale tile production, there are CNC tile cutting lines that can handle multiple tiles simultaneously, streamlining the manufacturing process. Moreover, CNC machines designed for specific tile materials, such as ceramic or natural stone, cater to the unique requirements of each material.

The applications of CNC tile machines

The applications of CNC tile machines extend across various industries, including construction, interior design, and art. In the construction sector, these machines are used to create custom-sized tiles for flooring, walls, and decorative elements. In the interior design industry, CNC tile machines are utilized to produce intricate patterns, murals, and customized tiles that add aesthetic value to spaces. Artists and craftsmen use these machines to explore the creative possibilities of tile art, crafting unique pieces and installations. In the manufacturing of furniture and home decor, CNC tile machines are employed to incorporate tiled surfaces into products such as tabletops, countertops, and mosaic designs. Additionally, in the automotive and aerospace industries, CNC tile machines are used to fabricate tiles for specialized applications, such as thermal protection systems and decorative features. Furthermore, in the production of monuments and architectural elements, these machines contribute to the precision cutting and shaping of tiles for memorials, facades, and public spaces.

The advantages of CNC tile machines

The use of CNC tile machines offers numerous advantages in terms of efficiency, precision, customization, and material optimization. These machines streamline the tile production process by automating cutting, shaping, and design tasks, reducing manual labor and enhancing overall operational efficiency. The high precision of CNC machines ensures consistent and accurate results, leading to seamless tile installations and minimizing material waste. Customization is a key benefit of CNC tile machines, allowing for the creation of unique designs, patterns, and sizes tailored to specific project requirements. The ability to work with various tile materials, including ceramics, porcelain, and natural stone, provides versatility in design and application. Additionally, CNC machines contribute to cost-effectiveness by optimizing material usage and reducing errors, leading to long-term savings in the tiling process.