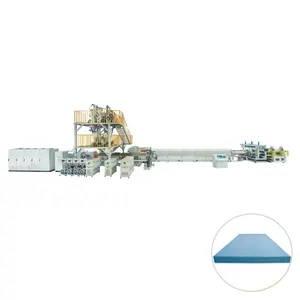

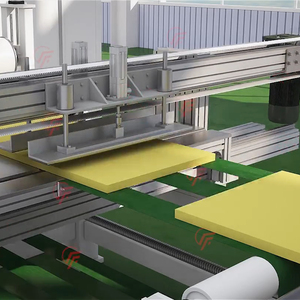

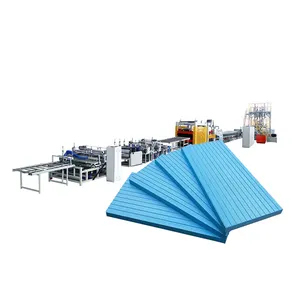

Make extrusion easy with Alibaba's wholesale plastic manufacturing catalog. Plastic extruders are machine tools that allow you to melt plastic pellets or other input materials and then reform them into useful products or sheets. co2 foaming board xps production line will be especially useful in sectors that rely on processing recycled plastics, allowing companies to close loops in their production cycle. That way, you can make manufacturing more efficient. The versatility of the extrusion process also allows you to achieve excellent results when creating plastic products.

Plastic extruders come in varying types, and you can sort through every style with Alibaba's search engine. Many co2 foaming board xps production line are tailored for use in pipe production, and you can set them to create whatever specifications of pipe work for you. When picking a pipe making machine, check that it can handle the plastic materials you use, and compare output rates to make sure it has the production capacity required. Alternatively, you could opt for a blow film extruder to create plastic sheets and films - a good option in the food packaging industry. And there are other specialist extruders for lab use that are smaller and more adaptable.

If you need co2 foaming board xps production line, the options will usually fall into either single screw or double screw categories. Generally speaking, double screw co2 foaming board xps production line will be more efficient and faster to use, as the inclusion of two screws effectively doubles production capacity. But the cost of these plastic extruders is higher and if your production needs are more modest a single screw version will be fine. All styles can be found at wholesale prices by searching at Alibaba.com - the ideal place to equip a plastics processing plant.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4