Introduction to Combined Busbar Machines

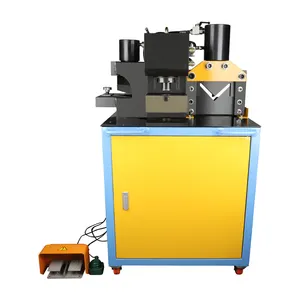

A combined busbar machine is a versatile piece of equipment designed for the efficient processing of busbars, which are essential components in electrical power distribution. This machinery integrates multiple functions such as punching, shearing, and bending, streamlining the manufacturing process for busbars used in a variety of industrial applications.

Functional Diversity and Applications

The multifunctional nature of a busbar processing machine allows it to execute a range of operations including embossing, slotting, and creating rounded corners. This adaptability makes it suitable for diverse industrial settings, particularly where precision and rapid production are paramount. Its application extends to electrical switchboards, power substations, and other domains requiring the manipulation of metal bars.

Construction and Material

Constructed with durability in mind, the busbar fabrication machine features components made from materials resistant to corrosion. The inclusion of linear guides and high precision ball screws ensures the machine operates with exactitude, delivering consistent results in busbar modification.

Design Features and Maintenance

Ease of maintenance is a key design aspect of the busbar manufacturing equipment. The innovative spring system connection mitigates the need for frequent hardware tightening, reducing downtime. Additionally, the user-friendly interface of the machine negates the necessity for extensive training, allowing operators to manage the equipment with minimal effort.

Types and Customization

Alibaba.com hosts a variety of busbar machines, each offering different specifications to meet the needs of various production scales. These machines come in an array of sizes and configurations, providing options for customization without the reliance on specific brands.

Efficiency and Automation

The hydraulic busbar machine is engineered for efficiency, capable of bending robust metal bars, including aluminum and copper, with precision. Automation is at the forefront of its operation, requiring only the initiation or cessation of the process by the operator, which enhances the production flow and reduces manual labor.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4