Introduction to Concrete Box Culverts Mould

Concrete box culverts are essential components in modern infrastructure, facilitating the flow of water and serving as passages under roads and railways. The concrete box culverts mould is a pivotal tool in their construction, shaping the concrete into durable structures that withstand environmental stress and load conditions. This introduction delves into the intricacies of these moulds, their types, applications, and features.

Types and Applications

There are various types of moulds for concrete box culverts, each designed to meet specific engineering and environmental requirements. From small-scale drainage systems to large underground passages, these moulds are crafted to produce culverts of different sizes and shapes. The application of these moulds spans across sectors such as transportation, water conservation, and urban development, highlighting their versatility in civil construction projects.

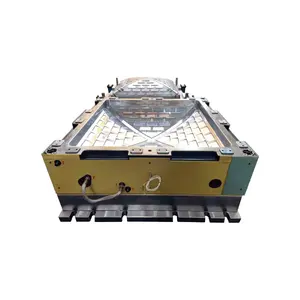

Features and Materials

The concrete box culverts mould is designed with features that ensure precision and durability. Typically made from robust materials like steel or iron, these moulds can withstand the rigors of concrete casting processes. The choice of material contributes to the mould's longevity and the quality of the finished culvert. Innovations in mould design also allow for customization, enabling the creation of culverts that meet specific design parameters.

Advantages of Using Quality Moulds

Utilizing a well-crafted concrete box culverts mould brings several advantages. It ensures uniformity and consistency in the production of culverts, which is crucial for their structural integrity. Additionally, a quality mould can reduce waste and increase efficiency in the manufacturing process, leading to cost-effective production without compromising on the performance of the culverts.

Optimizing Production with Standardized Features

Optimization of the production process is achievable by standardizing certain features of the concrete box culverts mould. Incorporating uniform lift bars, connection sizes, and clamp slots can simplify the manufacturing process, making the moulds more user-friendly and compatible with various production setups. This standardization can lead to significant improvements in operational efficiency.

Selecting the Right Mould for Your Project

Choosing the appropriate concrete box culverts mould is a critical decision that impacts the success of your project. Factors such as the specific application, desired durability, and production capacity should guide the selection process. The Alibaba.com platform connects buyers with experienced suppliers who can assist in selecting the right mould, ensuring that the final product aligns with project requirements.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4