Understanding Condenser and Evaporator Production Lines

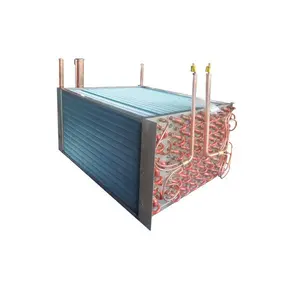

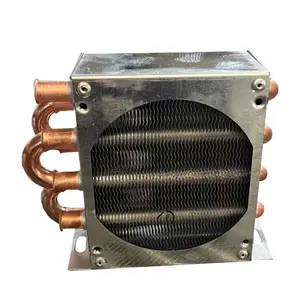

The condenser and evaporator production line is a specialized assembly system designed for the creation of key components in HVAC (Heating, Ventilation, and Air Conditioning) systems, refrigeration units, and various industrial applications. This category encompasses a range of machinery tailored to produce condensers and evaporators, which are crucial for thermal exchange processes.

Types and Components

Within the condenser and evaporator production line, there are multiple types of machinery, each serving a specific function. From coil bending machines to tube cutting and welding stations, the production line is equipped to handle various metals such as steel, stainless steel, and other alloys. The choice of material often depends on the intended application and required durability of the final product.

Applications and Industries Served

The versatility of a condenser and evaporator production line extends to its applications across different industries. These lines are not only pivotal in manufacturing plant settings but also serve machinery repair shops and retail sectors that require custom-made thermal exchange components. The adaptability of these production lines allows for their use in a multitude of environments and for various end-uses.

Technical Features and Support

A condenser and evaporator production line may come with a variety of technical support options, including online support and video technical assistance. Additionally, some suppliers offer the service of engineers who can assist with machinery operation overseas. The technical specifications of these production lines can vary, with voltage requirements typically around 380v, though this may differ based on the machinery model and regional standards.

Materials and Construction

The construction of equipment within a condenser and evaporator production line emphasizes durability and efficiency. The use of robust materials like metals ensures that the machinery can withstand the rigors of continuous operation. Stainless steel components are often utilized for their resistance to corrosion and ease of maintenance, which is critical in environments where moisture and refrigerants are present.

Advantages of Modern Production Lines

Modern condenser and evaporator production lines are designed to optimize production efficiency and product quality. The integration of automated systems and precision engineering contributes to the consistent output of components, meeting the demands of various sectors. These production lines are a testament to the advancements in manufacturing technology, aiming to deliver reliable performance and adaptability in component fabrication.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4