Top categories

Prefabricated Buildings

Countertops, Vanity Tops & Table Tops

Building & Industrial Glass

Mosaics

Metal Building Materials

Multifunctional Materials

Ladders & Scaffoldings

Mouldings

Corner Guards

Decorative Films

Formwork

Other Construction & Real Estate

Soundproofing Materials

Timber

Waterproofing Materials

Building Boards

About products and suppliers

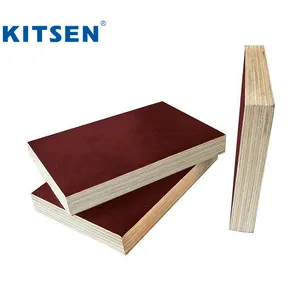

Introduction to Construction Plywood Film Faced Plywood

Construction plywood film faced plywood is a specialized material designed for demanding applications in various construction projects. This engineered wood product is known for its strength, durability, and smooth surface, making it an ideal choice for formwork and shuttering tasks.

Types and Features

Construction film faced plywood comes in several types, each tailored for specific uses. The common factor among them is a film coating, which provides a protective layer against moisture, wear, and chemicals. The core of this plywood is made from high-grade wood, ensuring uniformity in strength and stability.

Applications in Construction

The primary use of construction plywood film faced plywood is in creating molds for pouring concrete. Its ability to withstand high pressure and harsh conditions makes it a reliable choice for complex structures. Additionally, it is often used in building platforms, walls, and other large structures where a smooth finish is required.

Material and Advantages

The material composition of film faced plywood for construction includes layers of wood veneers bonded with strong adhesives. The film facing, usually made from phenolic or melamine, adds to its resilience. The advantages of using this plywood are its reusability, ease of cleaning, and resistance to cracking or warping.

Maintenance and Longevity

While construction film faced plywood is designed for durability, proper maintenance can extend its lifespan. It should be stored in dry conditions and cleaned after each use to prevent damage. Its longevity is a cost-effective feature for construction projects, reducing the need for frequent replacements.

Environmental Considerations

Sustainability is a concern in construction materials, and construction plywood film faced plywood addresses this by often being sourced from managed forests. The reusability factor also contributes to its environmental friendliness, reducing the impact on natural resources.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4