Popular in your industry

Related Searches:

Top categories

About copper billet casting mould

Introduction to Copper Billet Casting Moulds

Copper billet casting moulds are essential components in the metallurgical industry, used for shaping and solidifying copper into standardized billets. These moulds are crafted to withstand the high temperatures and corrosive nature of molten copper during the casting process. The precision of these moulds is critical, as they directly influence the quality and dimensions of the final billets.

Types and Applications

Copper billet casting moulds come in various designs, each tailored to specific casting methods and end-use applications. From simple, flat moulds for basic billets to complex geometries for specialized purposes, the diversity of these moulds meets the demands of industries ranging from electrical to construction. The application of these moulds is pivotal in producing copper billets that are later extruded or rolled into products such as wires, rods, and sheets.

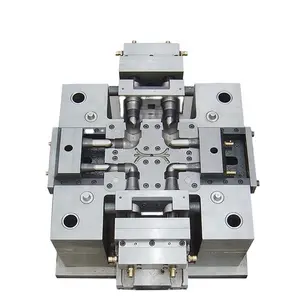

Features and Engineering

The design features of copper billet casting moulds are a testament to advanced engineering. They are characterized by their thermal conductivity and resistance to wear and deformation. The robust construction of these moulds ensures longevity and consistent performance under the rigorous conditions of copper casting. Precision engineering is evident in the moulds' ability to produce billets with exact dimensions and smooth surfaces, which is crucial for subsequent manufacturing processes.

Materials and Advantages

Typically made from high-grade, heat-resistant materials, copper billet casting moulds offer durability and efficiency. The materials selected for these moulds provide a balance between thermal conductivity and structural integrity, allowing for rapid cooling of the cast billet while maintaining the mould's shape. The advantages of using these specialized moulds include improved cycle times, reduced material wastage, and the production of billets with uniform physical properties.

Choosing the Right Mould

Selecting the appropriate copper billet casting mould is crucial for any casting project. Factors to consider include the mould's compatibility with the casting equipment, the desired dimensions of the billet, and the specific properties required for the end product. Utilizing the vast network of suppliers on Alibaba.com, buyers can find a mould that aligns with their project's specifications and material requirements.

Design for Manufacturing (DFM)

The process begins with a DFM, which is a comprehensive plan outlining how the copper billet casting mould will be fabricated. This plan is developed after a thorough analysis of the product design, ensuring that the mould is optimally designed for manufacturing efficiency and product quality. Once approved, the mould is crafted to the precise specifications of the DFM, ensuring that the final product meets the buyer's requirements.