Popular in your industry

Related Searches:

Top categories

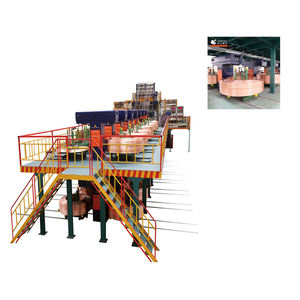

About copper rod upcaster plant

Introduction to Copper Rod Upcaster Plants

Copper rod upcaster plants are specialized facilities designed for the production of copper rods through the process of upcasting. These plants are integral to the metal manufacturing industry, providing the foundational materials necessary for a multitude of applications. The upcasting process involves melting copper cathodes and casting them into rods, which can then be drawn into wires and used in various electrical and construction projects.

Types and Applications

The versatility of copper rod upcaster plants is evident in the variety of types available, each suited to different production needs. From small-scale operations to large industrial setups, these plants cater to a broad spectrum of applications. The copper rods produced are essential components in electrical wiring, automotive industries, and electronic devices, underscoring the plant's significance in modern infrastructure and technology.

Features and Materials

A copper rod upcaster plant is characterized by its robust construction and the use of durable materials capable of withstanding the high temperatures required for copper melting and casting. The plant typically includes a melting furnace, holding furnace, casting machine, and cooling system, all engineered to work in unison for efficient production. The use of premium materials ensures the longevity and reliability of the plant's operation.

Advantages of Modern Upcasting

Modern copper rod upcaster plants boast several advantages, including enhanced energy efficiency, improved production rates, and superior rod quality. The implementation of advanced control systems allows for precise temperature regulation, contributing to the consistency of the rods produced. Furthermore, the automation of various plant components reduces the need for manual intervention, streamlining the production process.

Specifications and Customization

When selecting a copper rod upcaster plant, it is crucial to consider the specifications that align with your production requirements. These plants come in different sizes and capacities, with customization options available to meet specific operational needs. Components such as die casting machines, vacuum casting machines, and continuous casting machines can be tailored to accommodate the type of metal casting your business specializes in.

Investing in Copper Rod Upcasting

Investing in a copper rod upcaster plant requires careful consideration of the supplier's capabilities and the machinery's performance. Prospective buyers should seek out suppliers who can provide comprehensive information on the engineering and performance of their plants, ensuring that the investment aligns with their production goals and standards.